Press riveting

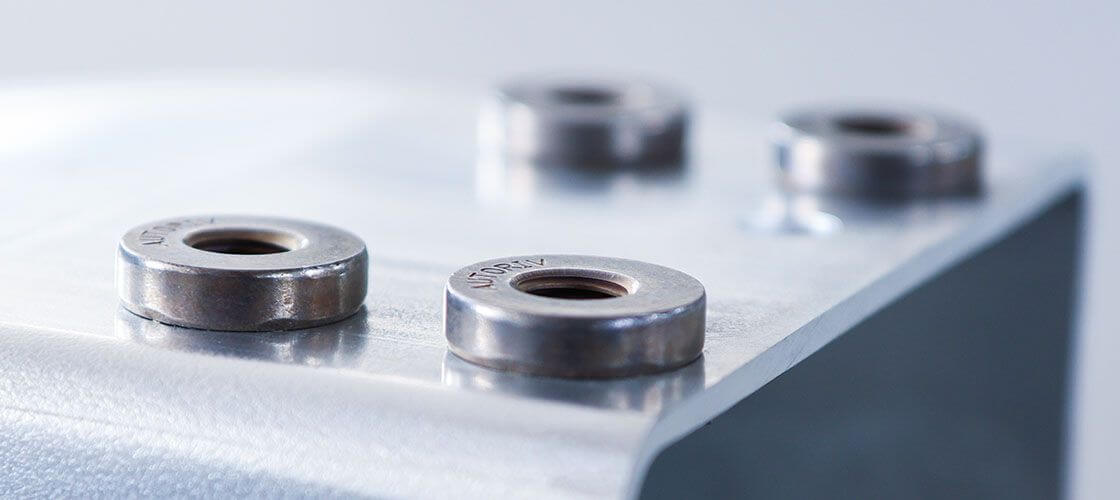

A rivet is pressed into a single- or multi-layered, pre-drilled component.

Within that fasteners joining process, a distinction is made between direct and indirect press riveting. When a rivet is placed into the pre-drill of a component before the protruding rivet shaft is deformed with high axial power by a riveting punch, this process is called direct press riveting. Indirect press riveting means that the deformation of a rivet happens simultaneously to the positioning into the pre-drill (the rivet is pressed against a stationary die).

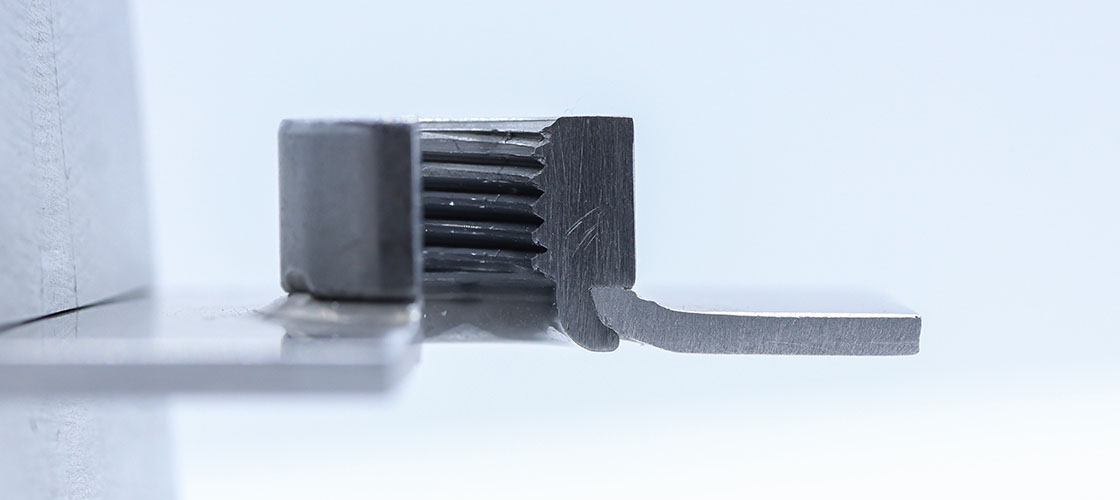

Rivet ball stud for extremely high loads

This joining method can be used not only for connecting parts. High-load functional fasteners like ball studs, which are used in hoods, trunks and doors, can also be riveted. In general, ball studs have to withstand extreme side loads. Therefore, we developed a high-load rivet ball stud and a corresponding BPR setting head for in-die / press automation.