Clipping

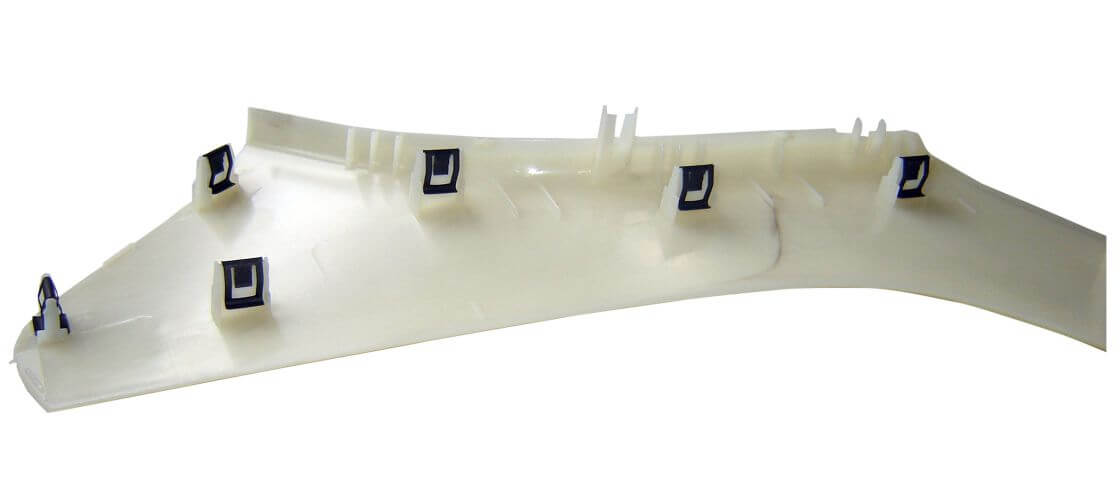

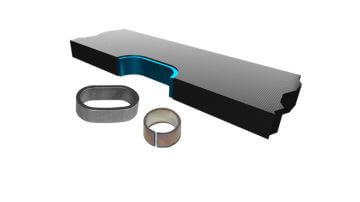

Precise pushing of clips and speed nuts on a component.

Clipping as a joining process of fasteners, is common within components that do not allow threads or deformation in the fastening process. It is also suitable with components that require large position tolerances for the mounting.