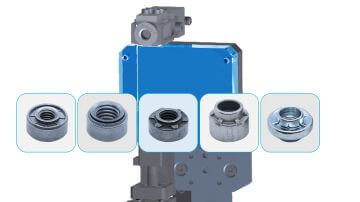

Setting head for spacers, standoffs, high nuts

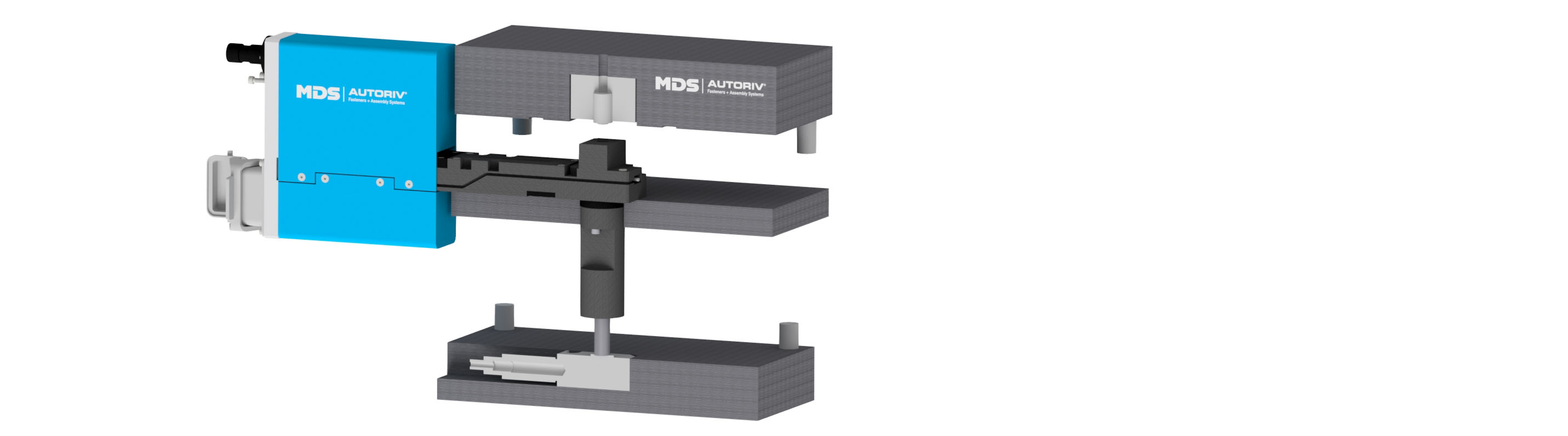

Installation under the press in punching and forming tools

The setting head HRN (High Riveting Nut) is an assembly system for progressive dies and transfer dies. The punching head is installed in the press to insert spacers / standoffs and high nuts into sheet metal components during the press process.

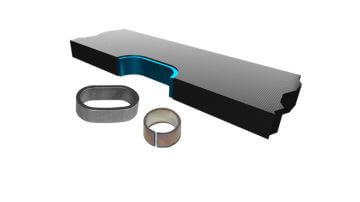

The setting head processes cylindrical fasteners with the ratio: height greater than diameter.

Depending on the type of tool and the press, there are different applications for the punching head

- Progressive dies with or without automatic mode signal from the press

- Transfer dies, with or without automatic mode signal from the press and with querying sheet metal in the die or in the gripper

Contact us

Our customer service will help you with any questions!

Installation and processing

The setting head can be installed in the tool so that spacers / standoffs can be set in the sheet metal from either top or bottom.

Storage of additional fasteners in the punching head allows for short cycle times or high output. This ensures consistent production.

Function

Setting process

The setting head is connected to the associated feeding system for press applications and is supplied with spacers / standoffs via a shot hose. The fasteners are transported by a pneumatic cylinder. After each press stroke, a new spacer moves to the setting position to be pressed into the part on the next stroke. When a spacer is in the setting position, a release signal is sent to the press. Without a release signal, the press stops.

Main process

The main process co-ordinates the part request to the feeding system. It ensures that the spacers / standoffs are moved to the setting position on time and monitors the press strokes by interrogating the press cams.

Pressing

The spacer / standoff is pressed into a sheet metal part from the setting position by the press-in mandrel. If no workpiece is present during a press stroke, no spacer is moved to the setting position. The plunger remains at top dead center due to blank sensing. An idle stroke is performed.

Air supply

A pneumatic connection on the feed system transfers compressed air to the setting head. This connection supplies the permanent air, the pneumatic cylinder for the slider and, optionally, the press-in mandrel.

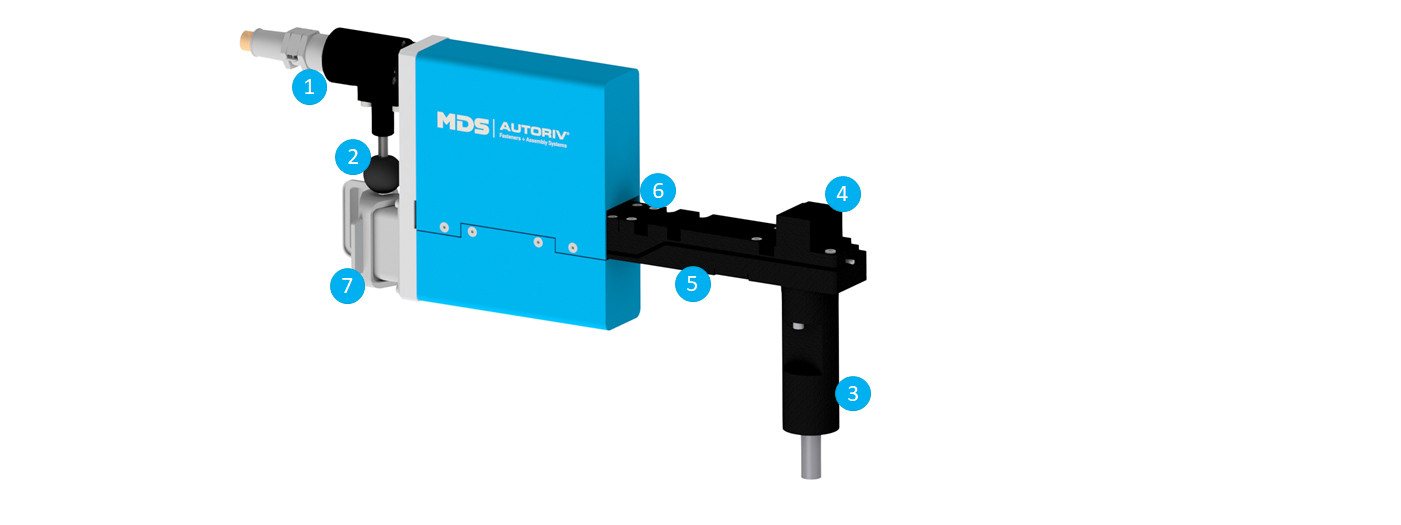

Components

Connector plug (1)

The connector plug is used to connect the shot tube to the setting head. The coupling is held in place by a locking pin (2) on the connector plug of the punching head. The spacer is transported into the accumulation path via a nut supply.

Plunger (3)

The plunger houses the press-in mandrel, which presses the spacers / standoffs into the sheet metal component. The mandrel is actuated by closing the press and transmits the compression force to the fastener. When the press is opened, the mandrel is pneumatically returned to the home position.

Impact piece (4)

The impact piece guides the spacer during the press-in process. This is precisely matched to the position in the tool and fastener type.

Accumulation path (5)

The setting head includes an accumulation path. It is used to store additional spacers / standoffs in the punching head to compensate for feed fluctuatons. A pneumatic cylinder pushes the fasteners forward to the setting position. The accumulation path ensures consistent production.

Feed cylinder (6)

The forward feed pushes the spacer / standoff forward to fill the accumulation path.

Multifunctional hose connector (7)

All signals are transmitted from the setting head to the feeding system via the multifunctional hose. The multifunctional hose also provides pneumatic supply to the punching head.

Highlights

High production reliability and quality

All important functions in the setting head are sensor-monitored with communication to the feeding system to stop the press in case of a malfunction well before top dead center (TDC) and thus avoid die damage.

Fast stroke rates

If a spacer / standoff is in the setting position and still being processed, the next spacer can already be reloaded. The next fastener can therefore be shot into the setting head in parallel with the processing of one fastener. This means that higher processing speeds can be achieved even with long shot hose lengths.

Safety during coil changes and with empty parts in production (transfer dies)

The feed cylinder only moves to the set position when a spacer is to be installed. Transfer die: If there is no workpiece, the feed cylinder does not move to the set position. It moves when a workpiece is present. The empty part sensor is either in the transfer grippers or in the tool itself. Coil change: When a coil change is required, the feed cylinder remains in the home position and the coil can be retracted as if there were no setting head installed in the tool.

Quick commissioning

The setting head has quick-release couplings for the shot hose and the multifunction hose for communication with the feeding system. There is no need to connect individual cables. This saves time and eliminates connection errors.

Technical data

Installation width:

Pneumatic supply:

Control voltage:

Press-in force / path:

Cycle time:

Interfering edge / Possible component depth:

Working direction:

*Depending on the fastener and length of the shot hose.

50 / 60 / 70 / 80 mm

6 bar from feed system

24 V / DC from feeding system

tool-dependent

up to 60 cycles/min*

according to customer requirements

vertical in both directions

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!