ACNS clinch stud

for automated feeding and processing

Clinch stud / screw for conventional performance requirements and suitable for thick metal sheets. In use at Heavy Trucks OEMs in the USA. Widely used at Tier1 level.

Sheet thickness - Used for metal sheets with thicknesses from 2mm upwards without limitation

Thread size - M5, M6, M8, M10, M12

Workpiece material - Steel, aluminum, copper, magnesium

Outer diameter - Large

Pull-through force - High

Torque - Very high

Push-out force - High

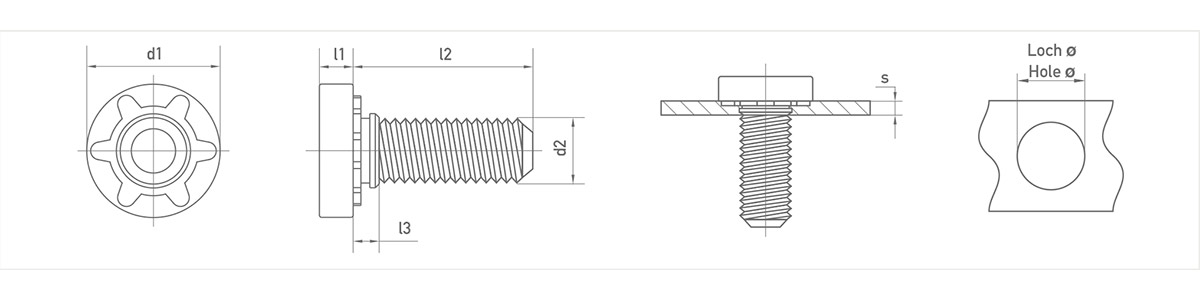

| Thread (d2) | Head diameter in mm (d1) | Head height in mm (l1) | Max. collar height in mm (l3) | Min. sheet thickness in mm (s) | Polot hole diameter in mm (Ø -0.1) | Thread length in mm (l2) |

|---|---|---|---|---|---|---|

| M5 | 8.75 | 1.75 | 3.00 | 2.00 | 5.85 | 10 / 12 / 16 / 20 / 25 |

| M6 | 11.00 | 2.10 | 3.00 | 2.00 | 6.85 | 12/ 16 / 20 / 25 / 30 |

| M8 | 15.25 | 2.80 | 3.00 | 2.00 | 8.85 | 16 / 20 / 25 / 30 / 35 / 40 |

| M10 | 19.75 | 3.50 | 3.00 | 2.00 | 10.85 | 20 / 25 / 30 / 35 / 40 / 45 / 50 |

| M12 | 20.00 | 3.80 | 3.00 | 2.00 | 12.85 | 20 / 25 / 30 / 35 / 40 / 45 / 50 |

Tolerances according to ISO 2768-m.

| Thread | Material | Sheet thickness (mm) | Press-in force (kN) | Push out force (kN) | Torsional strength (Nm) |

|---|---|---|---|---|---|

| M5 | Aluminum | 2.0 | 13.00 | 0.80 | 5.4 |

| M5 | Steel | 2.0 | 26.00 | 1.50 | 7.6 |

| M6 | Aluminum | 2.0 | 29.00 | 1.27 | 14 |

| M6 | Steel | 2.0 | 33.00 | 1.75 | 14 |

| M8 | Aluminum | 2.3 | 35.60 | 1.70 | 30 |

| M8 | Steel | 2.3 | 44.50 | 2.20 | 30 |

| M10 | Aluminum | 2.3 | 40.00 | 2.44 | 36 |

| M10 | Steel | 2.3 | 54.00 | 3.47 | 49 |

These values are for orientation only and are not binding.

Tests were conducted in steel H320 LA and aluminum EN AW-5754.

| Thread proof load | Thread length | Thread ends | Thread tolerance | Thread coating as an option | Surface protection |

|---|---|---|---|---|---|

| according to class 8.8, 9.8, 10.9 possible | according to customer requirements | according to standard, as well as MaThread | 6g, 6h | Nycote, Precote | Various surface coatings possible |

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!

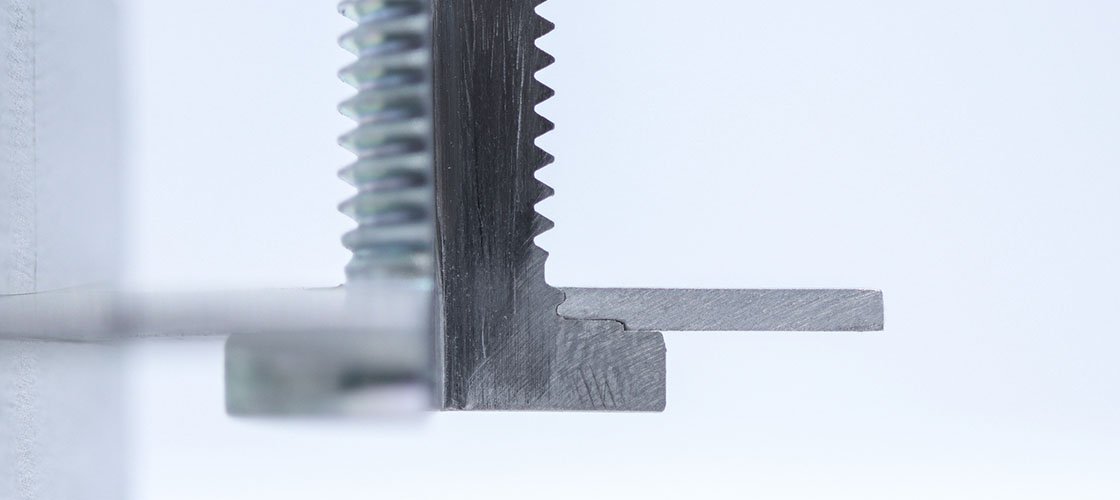

Application and function

Suitable for: Insertion in metal sheets with tensile strength less than 600N/mm². It can be used in galvanized, painted metal sheets

Sheet metal bottom: Flat without indentation, optimal fastening characteristics (clamping with a large surface area)

Pilot hole preparation: Pre-punched pilot hole according to AUTORIV specifications

Die: Use of a flat die (optimal downtimes)

Installation: Torque absorbers move and shape the material into the collar undercut

Outer diameter - pull through force: Large head diameter, also suitable for aluminum applications, good pull through force

Under-head serration - torque: Strong under-head ribs for high torque absorption

Collar - push out force: Collar with undercut to provide push out forces

Highlights

Lower risk of warping of workpieces, especially with many setting positions

- Lower risk of warping of work pieces

- Flat sheet metal bottom with largest surface possible for the preload through tightening

- No diversity, less stock requirement

- No risk of mix-up (Incorrect fasteners in incorrect application)

- (Re-)use of existing automation / tooling, thus reduction of investment

Greater compensation possible with custom design, possible with suitable AUTORIV thread end

- Ensuring optimal pressing: No "Not-OK pressings" with risk of subsequent complaints and quality costs

- No frequent re-teaching of the robot necessary

- Ensuring high availability and output, thus cost reduction

- The stud lines up precisely with the position of the pilot hole due to the run-in phase at the undercut (very narrow position tolerances possible)

- Easier positioning compared to studs that are placed in narrow pilot holes

- Lower chip formation due to abrasion of the thread on the edge of the pilot hole