The spin-pull process enables automated assembly of clinch nuts and rivet nuts in one-sided joining positions, such as closed profiles. With thicker metal plates, a clinch nut or rivet nut can be combined with a washer / spacer. This structural connection of a nut, metal sheet and spacer is clearly superior to a blind rivet nut connection. There is a wide range of possible applications for the combination of a clinch nut and spacer with additional cost-saving potential in the manufacturing process.

Contents

- Disadvantages of a blind rivet nut

- Advantages of clinch nuts & rivet nuts

- Comparison of both fastener types

- Advantages of the spin-pull process

- Combination of clinch nut and spacer in use

- Detailed view of the spin-pull process

- Summary

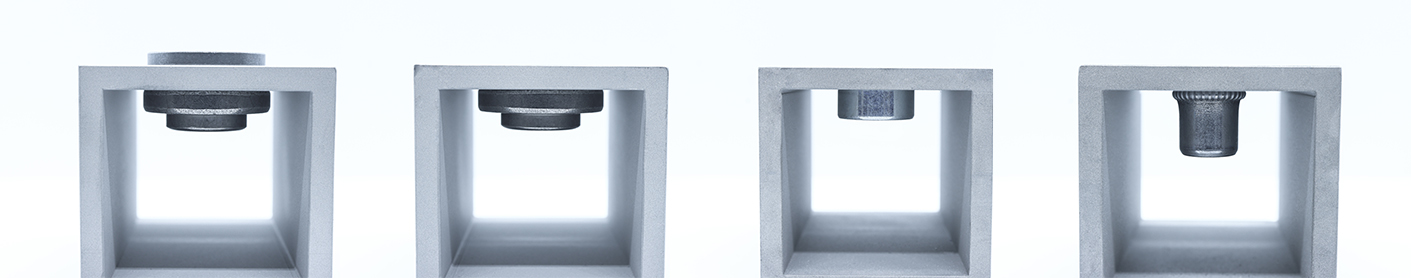

Disadvantages of a blind rivet nut

Strength of the screw joint

In closed profiles with accessibility from one side, the use of blind rivet nuts appears as a common solution. However, blind rivet nuts with the highest property class do not necessarily meet the expected strength requirements for the subsequent screw joint.

No preload

Regardless of the tightening torque, the joint only holds on the blind rivet bulge, as the additional metal sheet is screwed against the blind rivet nut head. Thus, there is no preload between the metal sheets. The blind rivet bulge has a small diameter and is not very thick. With lever loads from the side or axial loads, the blind rivet nut reaches its limits quite fast.

Consequences of high stress

The weakness of the blind rivet nut joint is the formed bulge. If the joint is highly stressed, metal sheet deformation, rivet collar deformation, tear-out of the rivet collar or pulling through the metal sheet may occur.

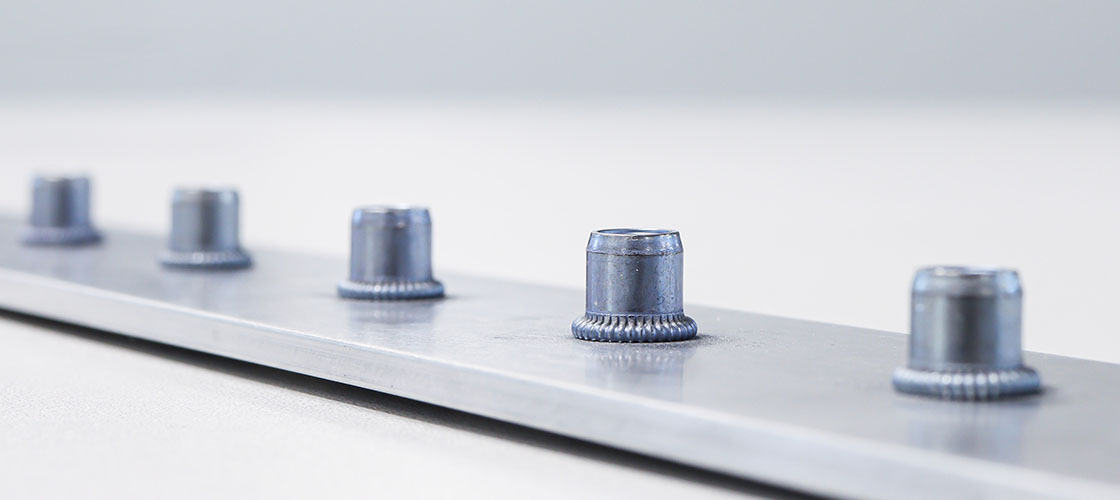

Advantages of clinch nuts & rivet nuts

High load capacity

The diameter and height of the clinch nut / rivet nut is significantly larger than the formed bulge of a blind rivet nut. Hence, this fastener type handles much higher forces from any load direction. Thus, for applications with high side loads (90-degree angle to the screw axis), we have suitable solutions that are used in series production.

Preload as significant advantage

With a clinch nut or rivet nut, a regular preload builds up between connected metal sheets at the later screw joint. Also when a spacer is used, there is a regular preload between the connection of the nut, metal sheet, spacer and the additional metal sheet. The built-up preload ensures a highly durable structural connection.

Cost reduction potential

The thread of a clinch nut is shorter than one of a blind rivet nut with same property class. This allows the use of a shorter screw, with cost reduction advantages regarding screws and screwing time. Due to the fact that our connection handles a much higher load capacity than the blind rivet nut, less screw joints may be required. Accordingly, here is also an additional potential for cost reduction.

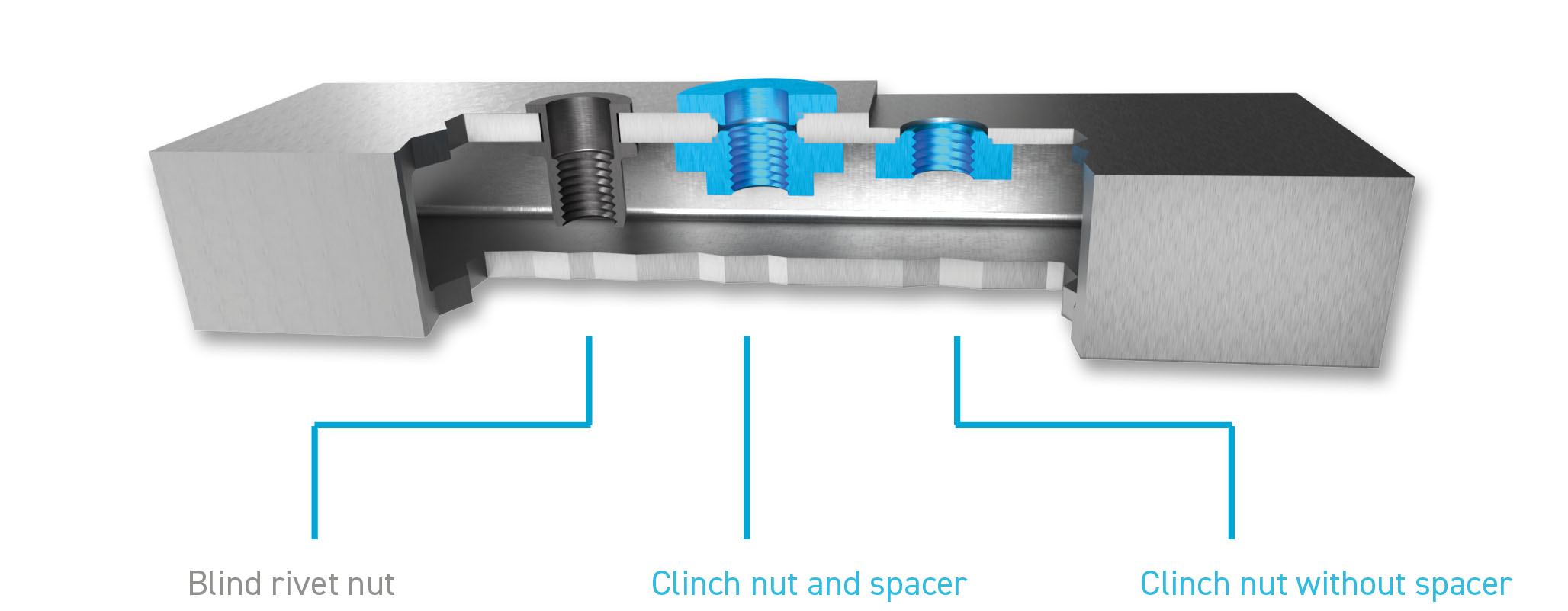

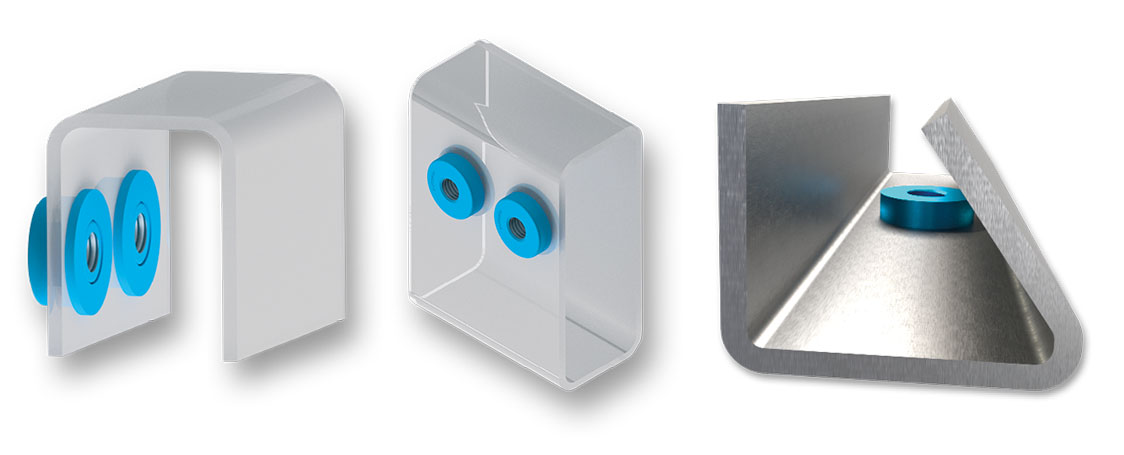

Comparison of both fastener types

The graphic shows both types of fasteners installed. The clinch nut can be used with or without a spacer, depending on the sheet metal thickness.

Blind rivet nut

Limited strength and low pull-through

- due to lower material hardness of a blind rivet nut

- due to less loadable small rivet bulge

- because there is no preload between the metal sheets

- as there is a risk of setting behavior within the connection

Clinch nut and spacer

High strength and high pull-through

- due to highly tempered nut

- due to larger and higher nut dimensions

- because regular preload is built up between the metal sheets

- because of higher dimensions, no setting behavior within the connection

Clinch nut without spacer

Also used as standalone fastener with the same strength advantages

Advantages of the spin-pull process

Innovative assembly process

- installation in closed-shape extrusion profiles and difficult-to-reach positions

- no need for opening the profile (the integrity of the part is not affected)

- one-sided access to assembly position

- high-strength structural connection contrary to blind rivet nuts

- series-proven and patented installation process

Process optimization and performance

- two work steps are combined into a single step

- cost and time reduction due to a single-step assembly

- fully automatic process-safe operation

- automatic tolerance compensation (+/-0,5mm)

- fast cycle time and high availability

- high torque, high pull through and push out forces

Many applications

- custom dimensions of clinch nut and spacer according to requirements

- in combination with a spacer also used as a chemical isolator

Combination of clinch nut and spacer in use

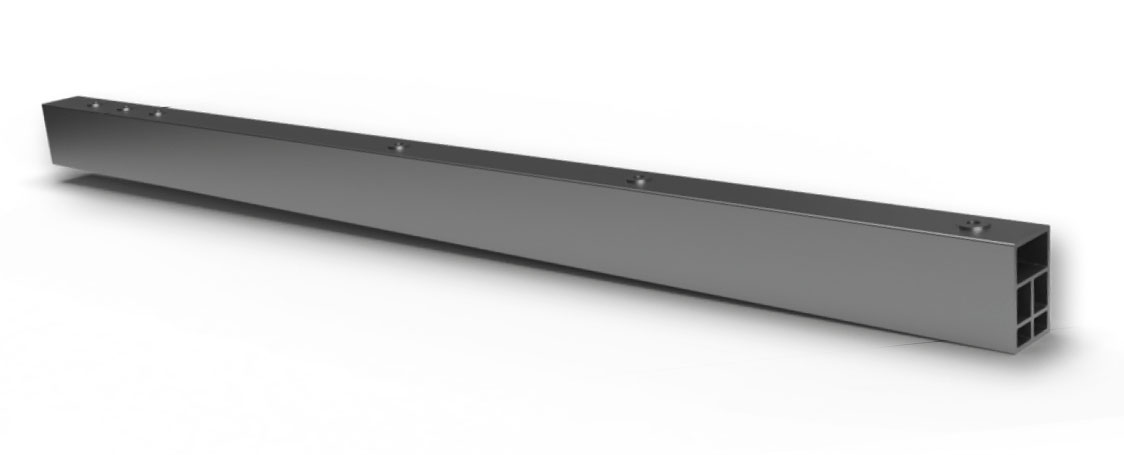

Use of nut-spacer-combination in various materials

- hydroformed parts

- aluminum profiles

- extruded profiles

- carbon fibre materials

Use of nut-spacer-combination within various parts

- crash boxes

- front-end modules and carriers

- battery trays in electric cars

Further applications for a nut-spacer-combination

- parts with undercut or overlap

- limited space or difficult-to-reach positions

- chemical isolation of aluminum and steel

- high-strength and high-load screw joints with one-sided accessibility

- Water and gas sealing can be realized according to customer requirements

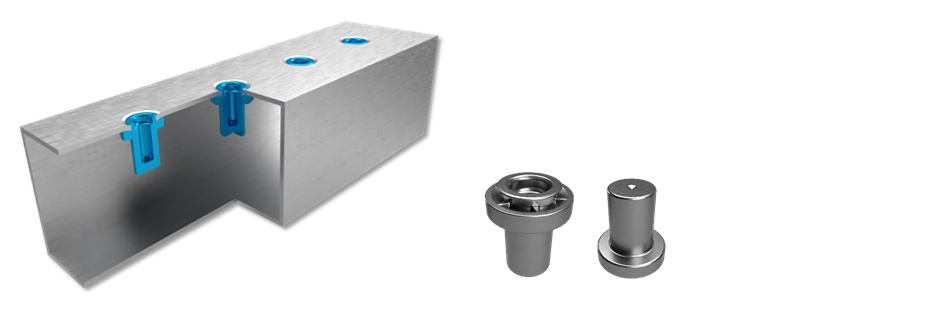

Detailed view of the spin-pull process

Various assembly systems are available for the automation of the spin-pull process. The installation of clinching fasteners can be implemented as in-die / press automation with suitable setting heads and feeding systems, as manual work station or within robotic tools.

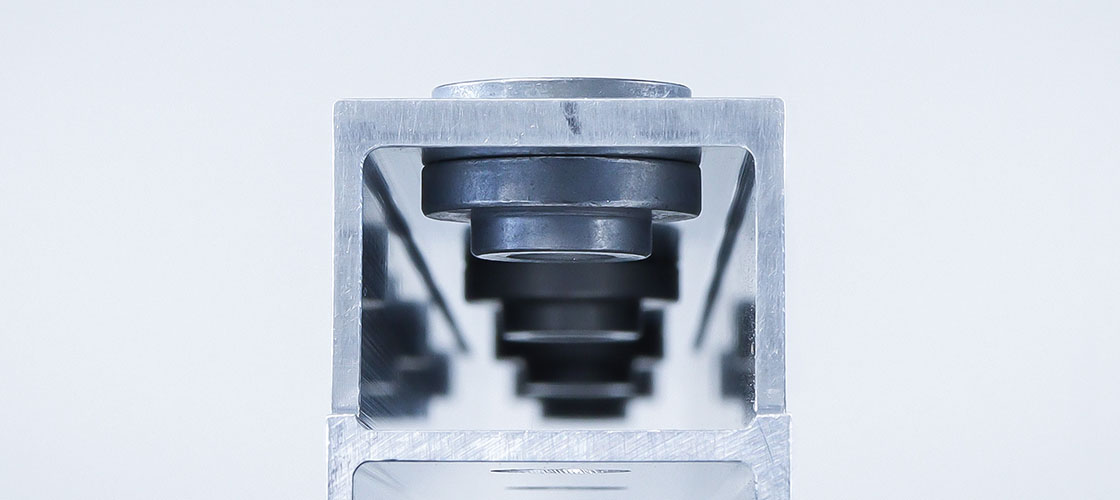

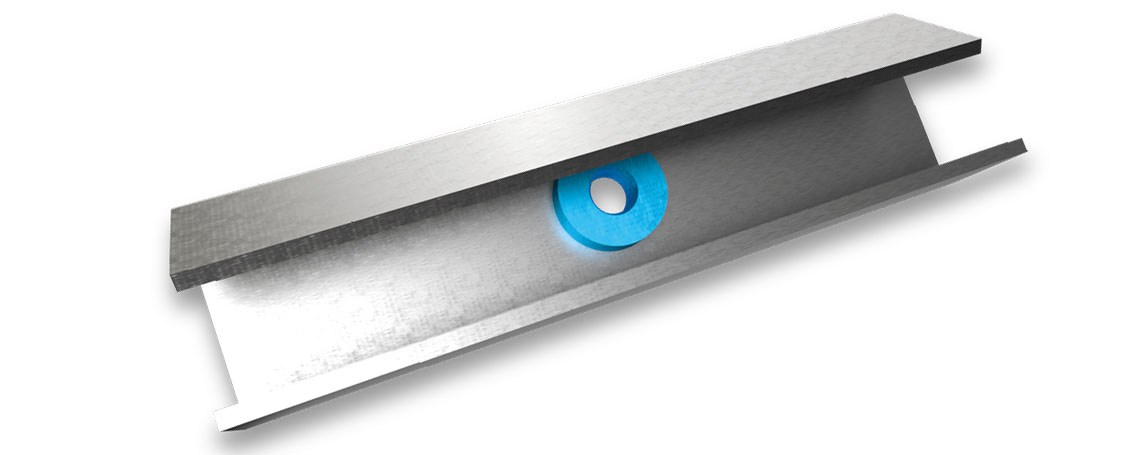

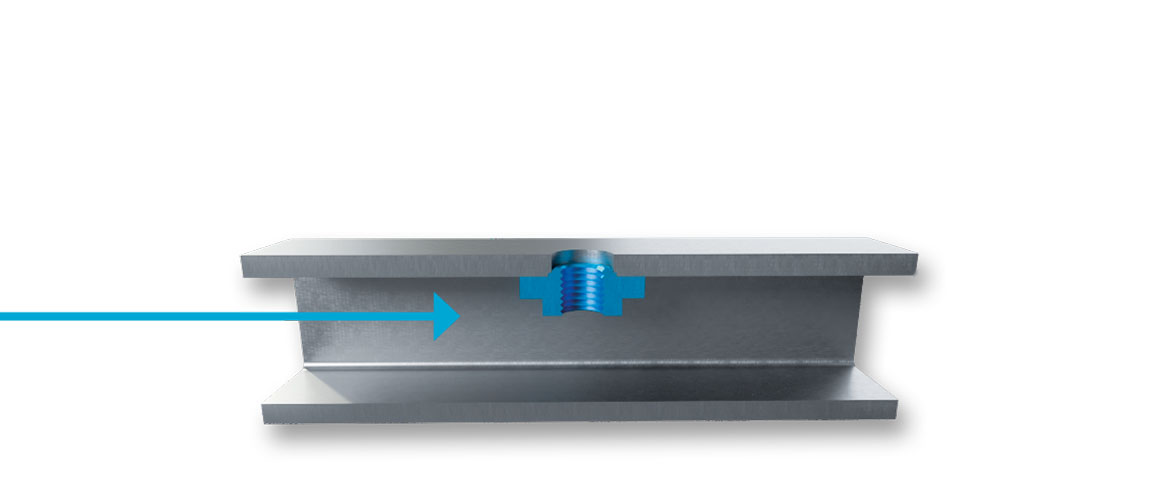

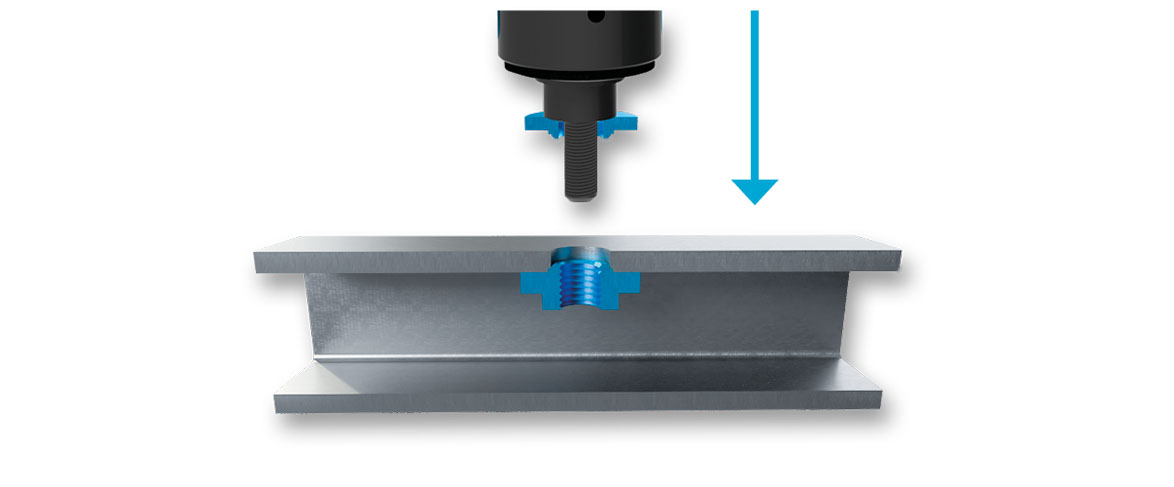

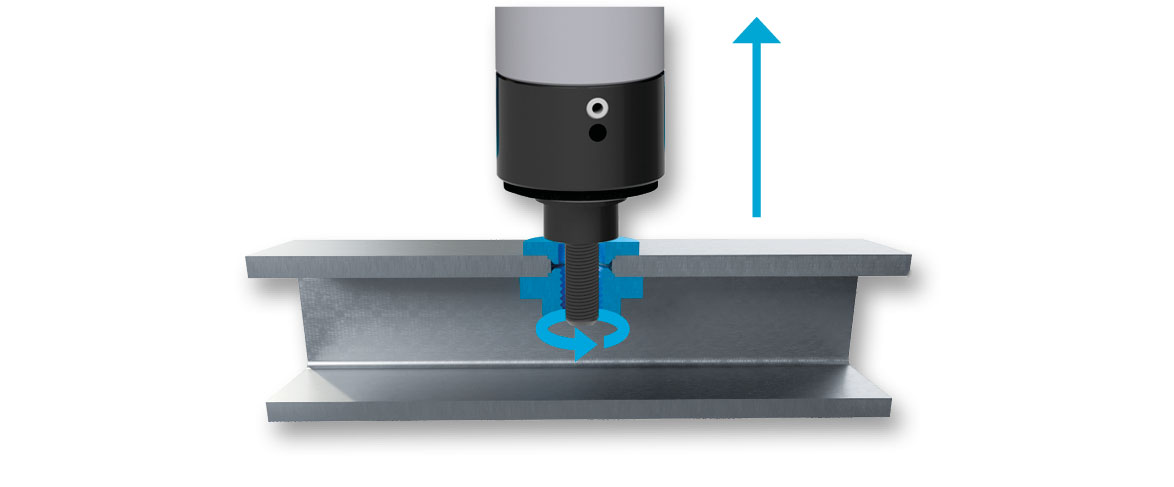

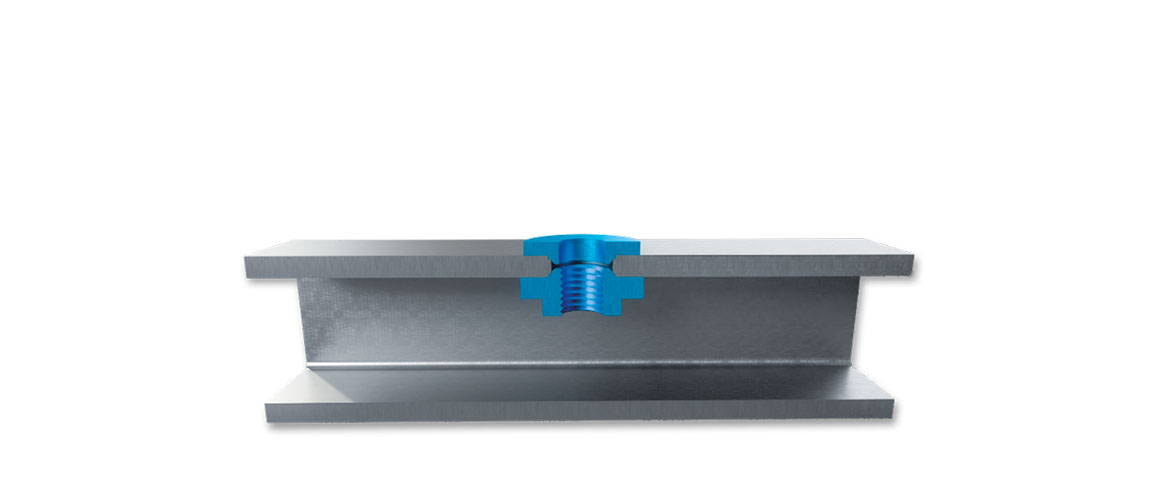

The graphics below show the sequence of a one-sided assembly in closed profile. The automated spin-pull process is performed in one step.

Operation step 1: A sliding unit carries the clinch nut to the pilot hole inside the profile. The nut is positioned under the pilot hole.

Operation step 2: The assembly unit moves into the pilot hole and is spinning into the nut underneath. The unit is carrying the spacer (optional).

Operation step 3: Axial pulling force is applied to the joint. The result is a form-fit connection between nut, metal sheet and spacer.

Operation step 4: The pulling mandrel is spinning out.

Summary

Blind rivet nut remains relevant

In general, the choice of an adequate fastener is made taking requirements into consideration. Therefore, the blind rivet nut is not losing its importance, we keep blind rivet fasteners in our portfolio. In many applications blind rivet nuts are absolutely adequate, for example serving as a screw joint in a plastic holder.

Spin-pull process considered as best solution

Our method is clearly superior when it comes to higher loads and is the only way to achieve a structural connection with one-sided accessibility. This solution creates new possibilities for handling closed profiles without opening them and affecting the stability of the part.