Modular feeding systems

Fully automated feeding systems for almost all fasteners

Feeding systems are an essential part of our machines. They ensure that our assembly systems are supplied with fasteners. A feeding system sorts the fasteners and delivers them individually to the setting unit.

The feeding system is set up to be easily accessible and outside the danger zone of the machine.

Your benefits

- Flexible use of the feeding system for further applications with the same fasteners

- High capacity of the system due to shorter cycle times

- Low space requirement

- Reduction of storage costs and internal logistics costs

Contact us

Our customer service will help you with any questions!

Contents

- Feeding systems for various applications

- Control of multiple setting units

- Feeding process

- Optional components

Feeding systems for various applications

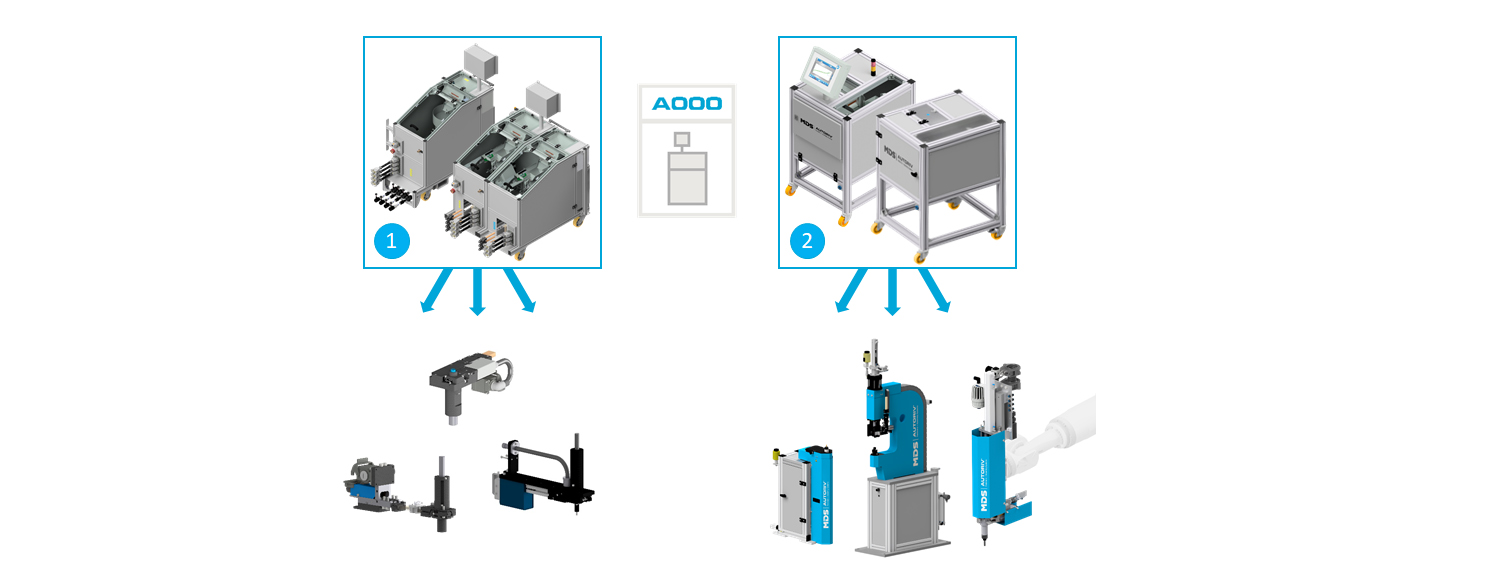

Conveying units

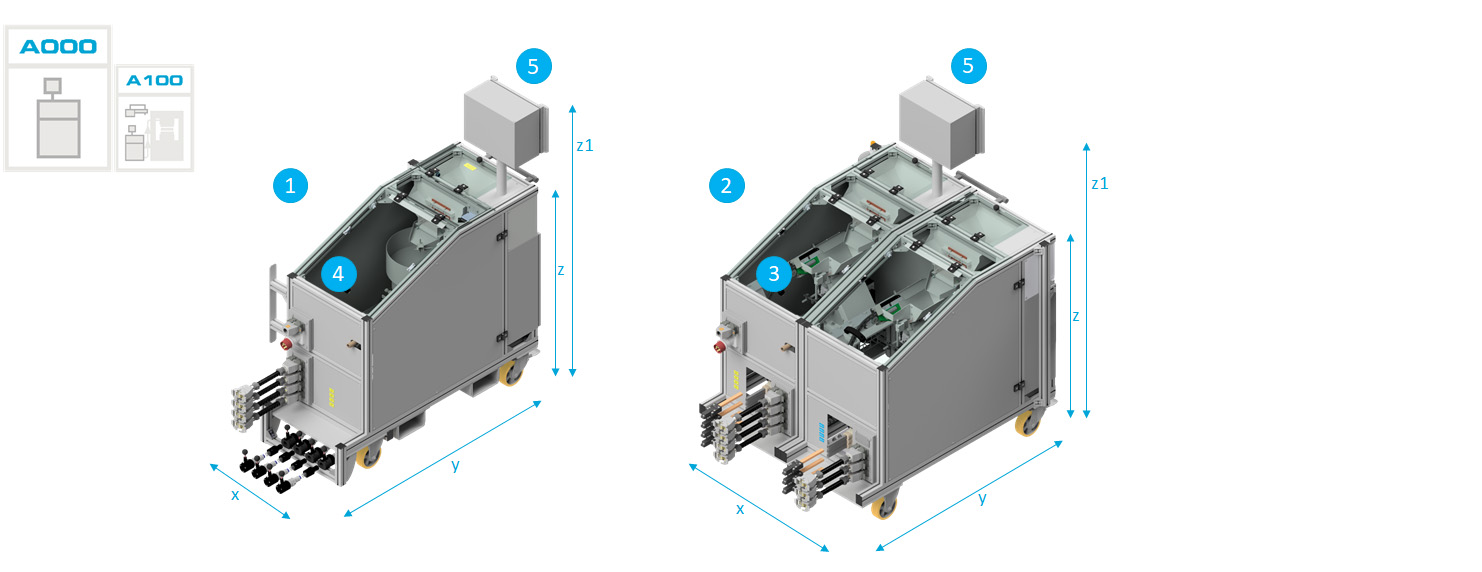

The feeding systems for A100 setting heads are available with one conveying unit (1) or two conveying units (2).

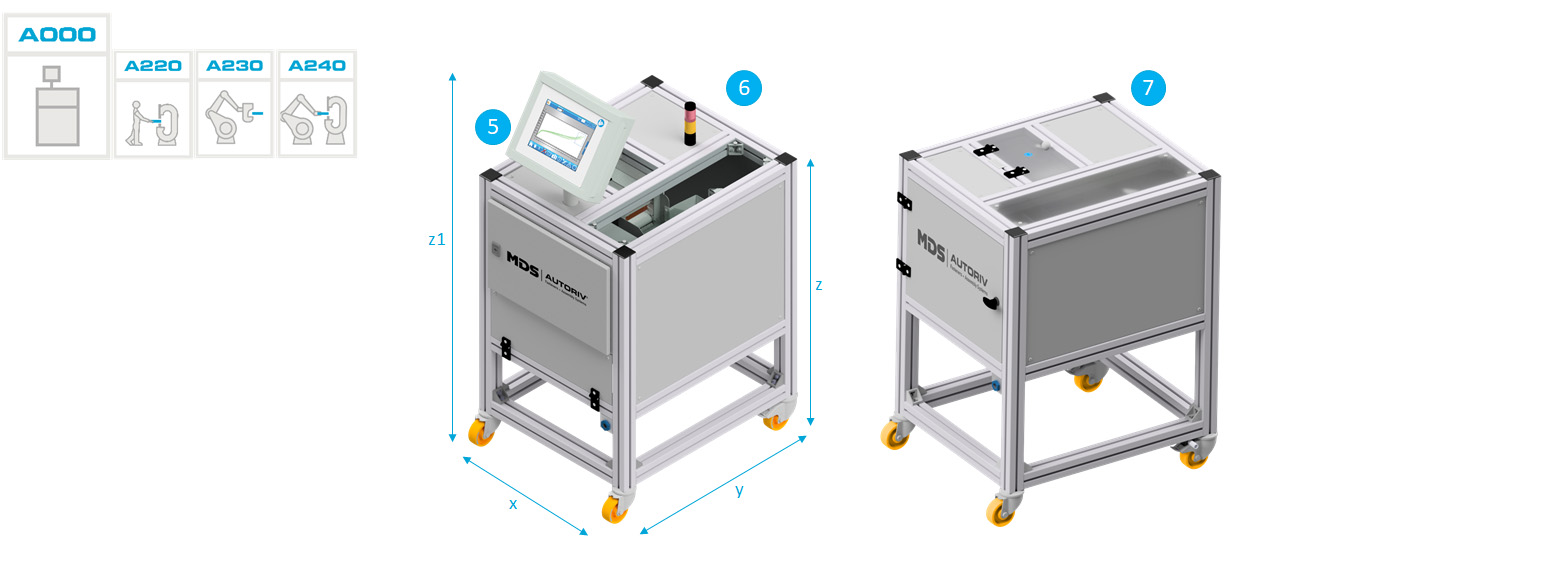

The feeding system for the A220 manual work station / A230 robotic tool / A240 robotic work station modules can also combine two conveying units. A master feeder unit with control function (6) and a slave feeder unit (7).

Depending on the type of fastener, we use two different conveyor systems.

FlexSys - system with step conveyor (3)

The step conveyor transports the fasteners onto the conveyor belt with the help of a cylinder and a sliding plate. Via the conveyor belt, the fasteners are further transported to a jam section. During transport, the fasteners are sorted and checked for correct position before entering the jam section.

ClassicSys - System with conveyor bowl (4)

The fasteners are conveyed and sorted by a shaker conveyor. Afterwards, a baffle checks the correct position of the fasteners.

Dimensions

Feeding system | X (mm) | Y (mm) | Z (mm) | Z1 (mm) |

|---|---|---|---|---|

for setting heads A100, one feeder (1) | 600 | 1600 | 1250 | 1850 |

for setting heads A100, two feeders (2) | 1200 | 1600 | 1250 | 1850 |

| for modules A220/A230/A240, one feeder (6) | 930 | 750 | 1130 | 1560 |

ClassicSys and FlexSys can also be combined into one feeding system with two conveying units.

The feeding system is operated via the ALL IN ONE controller module (5).

Control of multiple setting units

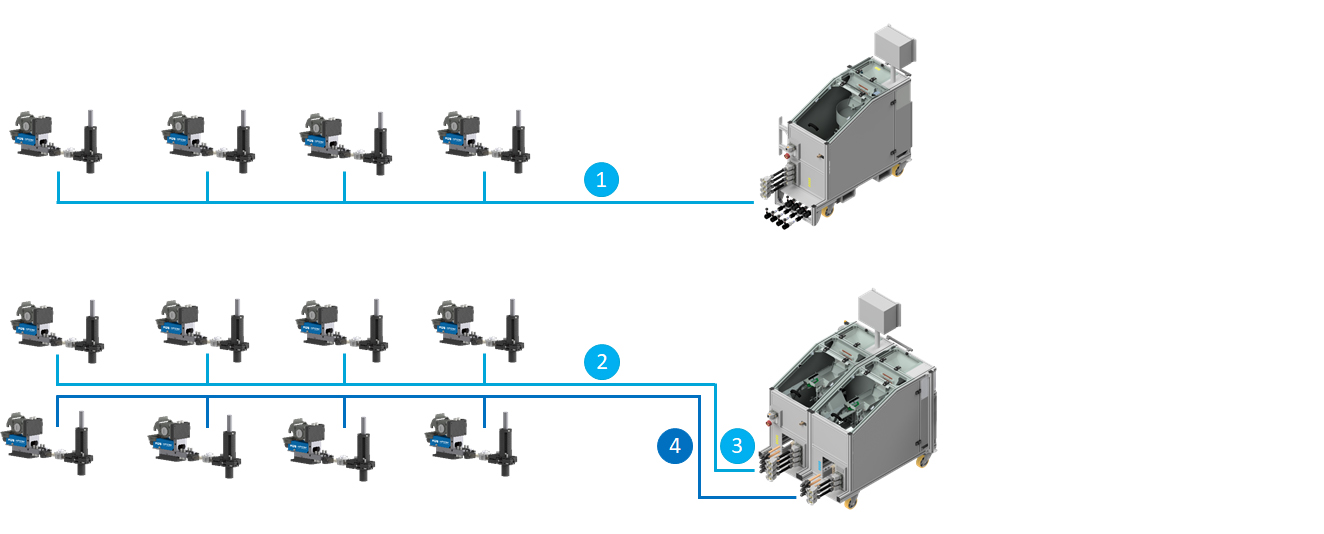

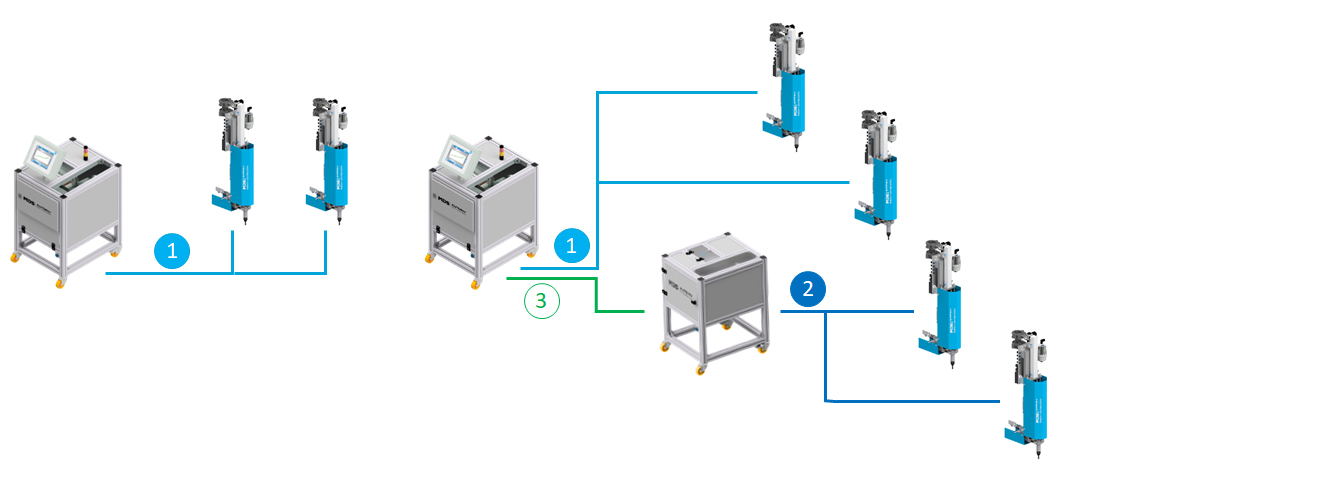

Feeding system for press applications - A100 setting heads

Up to four shot hoses can be connected to one feeding unit and thus four setting heads can be controlled, with the same fastener on all setting heads (1).

Two coupled conveyor units can be connected with eight shot hoses. The control of up to eight setting heads is thus possible (2), with one fastener type per conveyor unit (3) and (4).

Feeding system for modules A220/A230/A240

One feeder unit can supply two setting units with the same fastener (1) and (2), i.e. one type of fastener per feeder unit. A combination of two feeder units can thus drive up to four assembly systems (3). Both feeder units are operated with a single controller.

One feeder unit functions as the master device and sends the commands to the second feeder unit, the slave device. Both feeder units must be located in the same cell or in the same safety circuit. With regard to the interface connection, Profinet, Profibus, DeviceNet and EtherNet/IP are available.

Feeding process

Belt hopper

The feeder is filled with fasteners via the upper lid of a belt hopper. The belt hopper transports the fasteners towards the jam section. The belt is driven by an electric motor with gearbox. The conveying rate of the fasteners can be variably adjusted by a passage restriction. The drive motor of the conveyor belt is controlled by a jam sensor and switches off when the sensor is occupied.

Fill level

FlexSys - A fill level sensor ensures that the fill level is continuously checked. If the sensor is free, the belt hopper starts filling the step feeder. If the sensor remains unoccupied for a certain time, the machine reports a parts shortage.

ClassicSys - The fill level is checked via a pendulum query.

Jam section

The jam section is filled with fasteners aligned in the correct position. The fasteners pass through the jam section and are separated at the end. Depending on the feeding system, several jam sections can be installed. This means that several shot hoses can also be connected.

Separators

In the separation, the fastener is transported to the firing position by means of a cylinder. It is shot into the setting unit with compressed air via a shot hose.

The type of the separation depends on the type of fastener.

Depending on the shape and condition of the fasteners, we have various separations in our program:

- Cross-separators for nuts and studs

- Ejection separators for nuts, bolts and blind rivets

- Alternating separators for special nuts and glide bearing bushings

- Proofing separation for blind rivet nuts

Optional sensor

A "fastener injected" sensor can be mounted directly on the shot hose. The sensor detects whether a fastener has been shot from the separator into the shot tube.

Optional components

Hopper locking with barcode scanner

The feeder unit can be equipped with a scanner. The fasteners must be scanned before filling the hopper. The scanned barcode on the packaging is used to identify the correct fastener. Only then can the hopper lid be opened and the feeder unit loaded. In this way, errors due to incorrect filling of the feed system can be eliminated.

Oiling unit

The oiling unit oils the fasteners before separation in order to minimize frictional resistance during compression. This has a positive effect on both the longevity of the machine and the quality of the pressing process.

Compressed air reservoir

The compressed air reservoir provides an additional volume of compressed air, which is used to compensate for pressure fluctuations during operation. In a feeding system with two conveying units, it is also possible to equip only one conveying unit with a compressed air reservoir.

Hose suspension (feeder unit for A100 setting heads)

The hose suspension consists of two lugs between which the shot hose or multifunction hose can be rolled up. Depending on the design of the feeder unit, the suspension can be attached on one or both sides.

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!