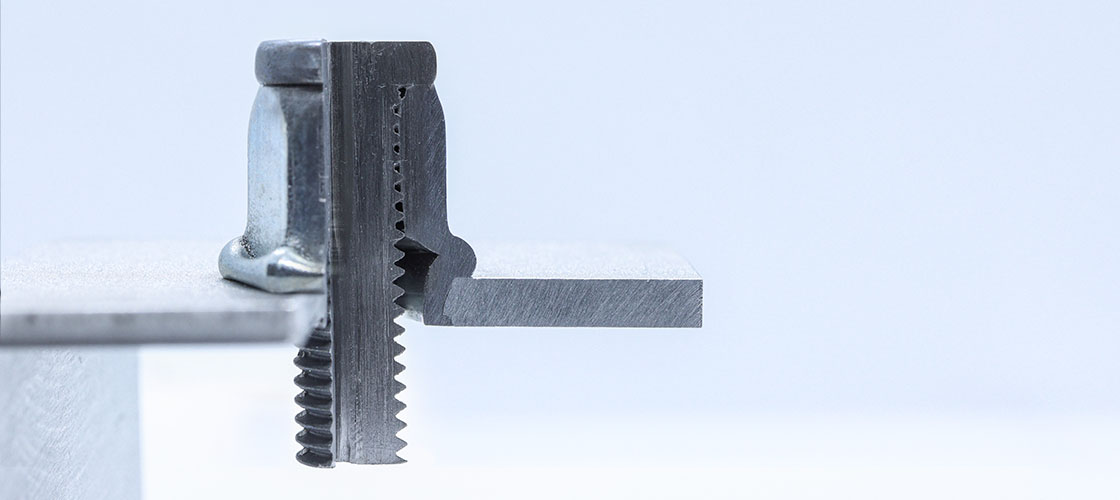

Blind rivet stud hexagonal / fullhex

for automated feeding and processing

Blind rivet stud / screw with hexagonal / fullhex shank for all-purpose application. It is used in hard materials and is suitable for heavy-duty applications. In use at car manufacturer OEMs in Germany, Europe and the USA.

Grip range - 0.5mm to 3mm in standard. In general, larger grip ranges are possible

Thread size - M4, M5, M6, M8

Fastener material - Steel, stainless steel, aluminum

Workpiece material - Suitable for all materials

Available with various head diameters and head heights:

Head geometry Push out force

Small / flush head Low

Large flange Very high

Body Shape Spin-out resistance

Fullhex Very high

For more details, please refer to Blind rivet nut hexagonal / fullhex

| Thread proof load | Thread length | Thread end | Thread tolerance | Thread coating as an option | Surface protection | Special designs |

|---|---|---|---|---|---|---|

| Thread proof load according to strength class 8.8, 10.9, 12.9 possible | according to customer requirements | according to standard, as well as MaThread | 6g, 6h, 6e | Nycote, Precote | Various surface coatings possible, according to customer requirements | Wedged head, large/ reinforced head, closed end, sealed head / sprayed proof, high strength thread, internally floating thread (nut cage) for tolerance compensation |

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!

Application and function

Suitable for: Suitable for all material variants

Pilot hole preparation: Hex-shaped pilot hole

Preferred use: Especially for one-sided joining positions e.g. difficult-to-reach positions, parts with undercut or overlap, closed profiles

Spin-out resistance – Hexagonal body vs. round body design: In comparison to blind rivet studs / screws with a round body, the hexagonal shank provides significantly higher spin-out resistance, especially in harder sheet metal.

However, the requirement for using blind rivet fasteners with a hex body is that a hex-shaped pilot hole can be punched into the component. For heavy-duty applications, fullhex blind rivet studs are recommended.

Push-out force - Larger head diameter vs. countersunk head: For high push-out forces, blind rivet studs with larger head diameters and head heights are recommended. Blind rivet fasteners with a small countersunk head have only low push-out forces.

However, their advantage is that the created connection is almost flush with the sheet metal surface. The countersunk head is almost completely embedded into the sheet, so there is only a minor excess of the head above the sheet surface.

If near flushness is required, blind rivet fasteners with a countersunk head should be considered. Other than that, a larger head is recommended due to the higher push-out forces.