Hand-held setting tool

for processing blind rivet fasteners

The A210 assembly system is a hand-held tool for processing blind rivet nuts and studs.

The hand tool is pneumatically controlled and is equipped with a sensor system for force-displacement evaluation. A separate pressure amplifier generates sufficient force to set the blind rivet nuts and blind rivet studs. The tool is particularly suitable for setting blind rivet fasteners in hard-to-reach places.

Fasteners - blind rivet nuts and blind rivet studs

Body shape - round, hexagonal / fullhex, partial hexagonal / halfhex

Thread size - M8, M10, M12, M16

Advantages of the tool

- Processing of components with difficult accessibility

- Quick-change mandrel for different sizes of blind rivet nuts

- Force-displacement controlled processing of blind rivet fasteners

- Process monitoring with force-displacement evaluation

- Ergonomic, compact design

- Use of up to four setting tools with one controller module

Setting process

The hand-held setting tool works according to the spin-pull principle. The blind rivet nut is turned by hand one to two thread turns onto the pulling mandrel. After spinning, the setting process can be started with the trigger. The blind rivet nut is caulked in the component via a pull stroke. At the end of the setting process, the mandrel thread spins out again. The return stroke or spin-out process is initiated automatically.

The joining position can only be accessible from one side for the setting process, such as in a closed profile.

The machined part must be prepared for the installation of the blind rivet nut, have an appropriate pilot hole and be easily accessible to the operator.

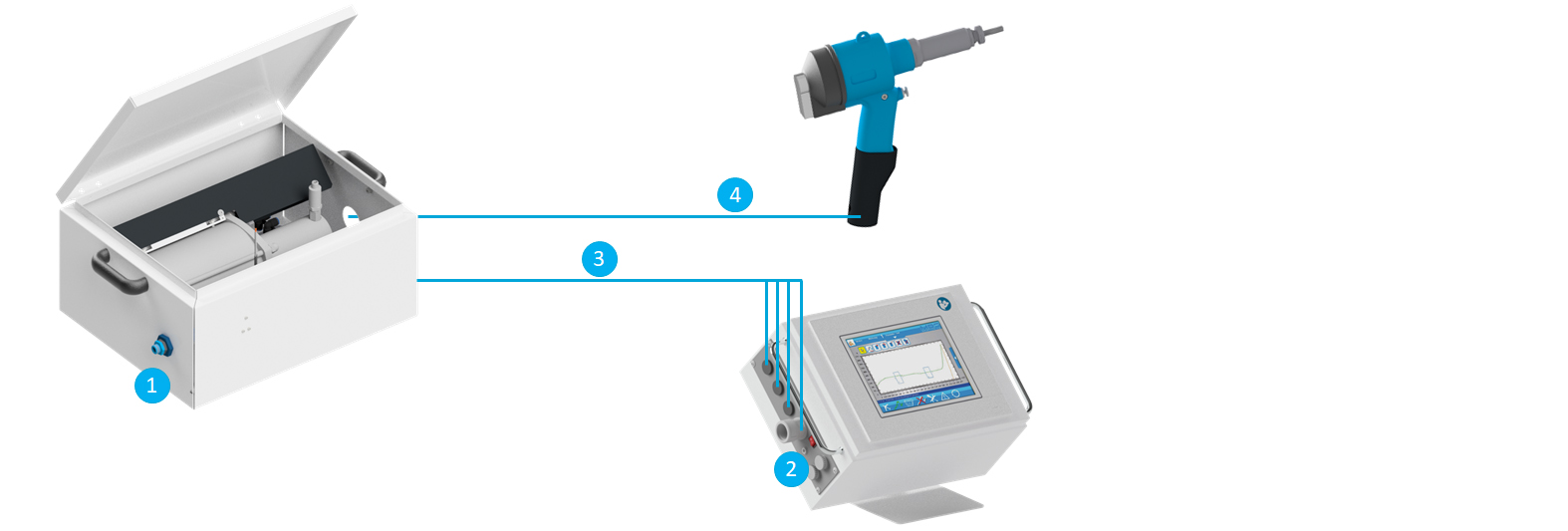

Components

Supply connections

1. Pneumatic connection of the hand-held tool

2. Power supply of the hand-held tool

3. Control line (sensor system) from controller to pressure amplifier unit

4. Supply line (control, voltage, pneumatics and hydraulics) from the pressure amplifier unit to the hand-held tool

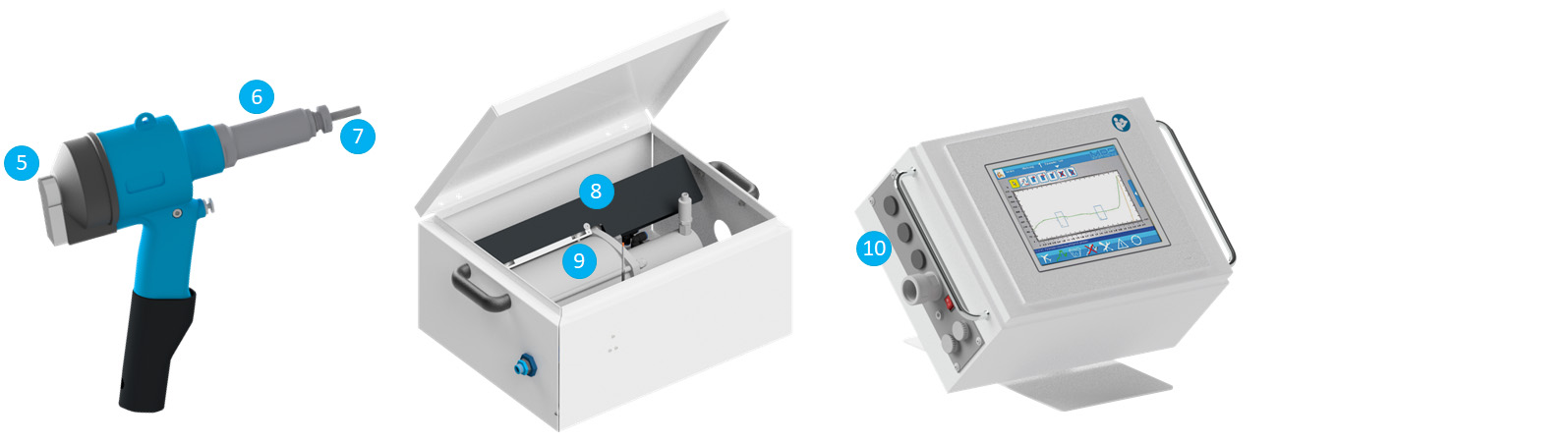

Hand-held setting tool

The hand tool is designed in such a way that the movements during operation only take place at the setting head. The handle is secured against slipping by preformed grips.

Pressure amplifier unit

The pressure amplifier unit contains an analog displacement sensor (8) and a pressure amplifier (9). The pressure amplifier unit and the hand tool are supplied pneumatically via a compressed air connection.

Controller module

The assembly system is controlled via a 10-inch operating panel with touchscreen. Up to four hand tools can be connected to one controller (10). The display can be split into four windows for simultaneous use of four hand tools.

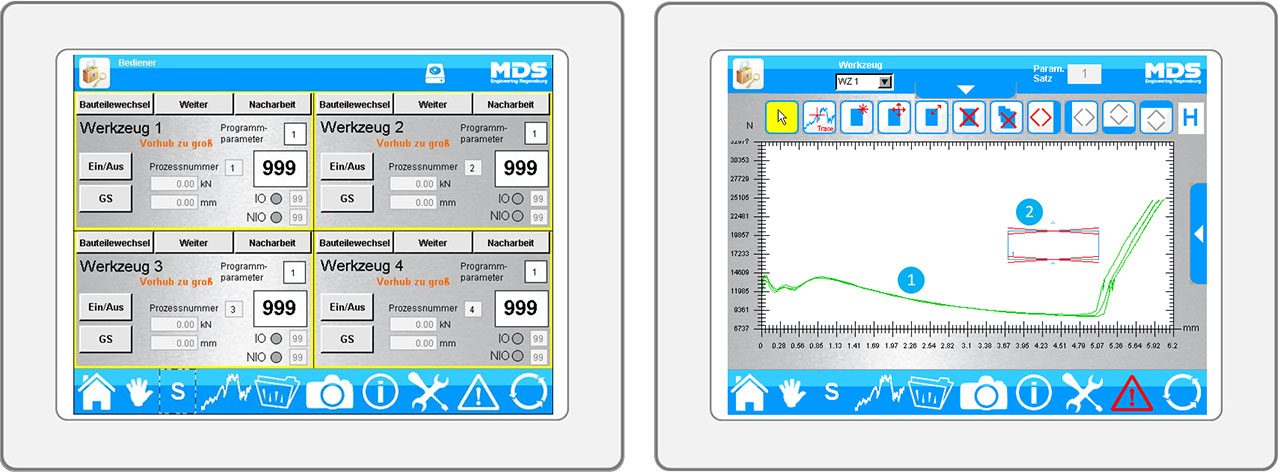

Control system

Working with the controller module

Each individual hand tool has a counting mechanism that monitors the number of blind rivet nuts to be set per component. When all blind rivet nuts have been successfully set in the component, the air of the setting tool is shut off to signal to the operator that the setting process for the component is complete. Only when a component replacement is triggered by a button on the controller module will the counter be reset and air be applied to the tool.

If a "Not OK" (NOK) evaluation is obtained during the setting process, the air is immediately removed from the setting tool to draw the operator's attention to the NOK result. The setting process can only be continued by pressing the "Next" button.

Coupling multiple setting tools

Setting tools can be linked by using the same process number. This means that these setting tools process the same component. Switching to a new component is possible when the tools have completed their setting process equally successfully.

Process evaluation

During each setting process, a force-displacement curve (1) is recorded using integrated sensors and displacement measurement systems. This represents the time course of the joining process - X-axis deformation in mm; Y-axis deformation force in N. Monitoring windows (2) can be used to qualitatively evaluate such force-displacement curves. If the curve is outside the defined window, it is declared as NOK.

Interface for external control / control software

An interface allows an external controller to control the assembly system instead of using the buttons on the operating panel. Therefore, control bits equivalent to the buttons on the panel are also available on this interface.

Technical data

Air pressure min. / max.

Air volume / cycle

Setting stroke max.

Setting force max. (version "standard" / "strong")

Cycle time (reference values - blind rivet nut steel M10)

Vibrations

Noise emissions

Projecting edge / component depth

Working direction

Lengths of the supply lines

Controller module to pressure amplifier unit

Pressure amplifier unit to hand tool

Dimensions (exterior)

Hand-held tool

Pressure amplifier unit

Controller module (plus connectors and plugs)

Weight

Hand-held tool

Pressure amplifier unit

Controller module

5 - 7 bar

9 liters / 5 bar

15 mm

35 KN / 80 kN

3 - 3,5 s

< 2.5 m/s²

LpA < 77 dB(A)

according to customer requirements

freely selectable

Version "standard" / "long"

4.57 m (15 feet) / 9.45 m (31 feet)

4.57 m (15 feet) / 7.62 m (25 feet)

approx. 300 x 300 x 100 mm

approx. 600 x 400 x 300 mm

approx. 500 x 400 x 360 mm

2.5 kg

20 kg

10 kg

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!