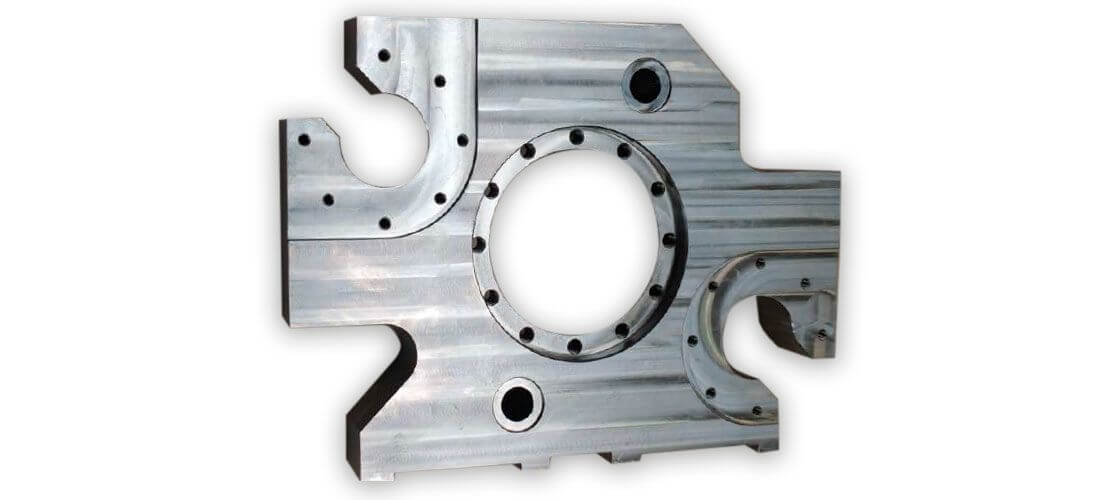

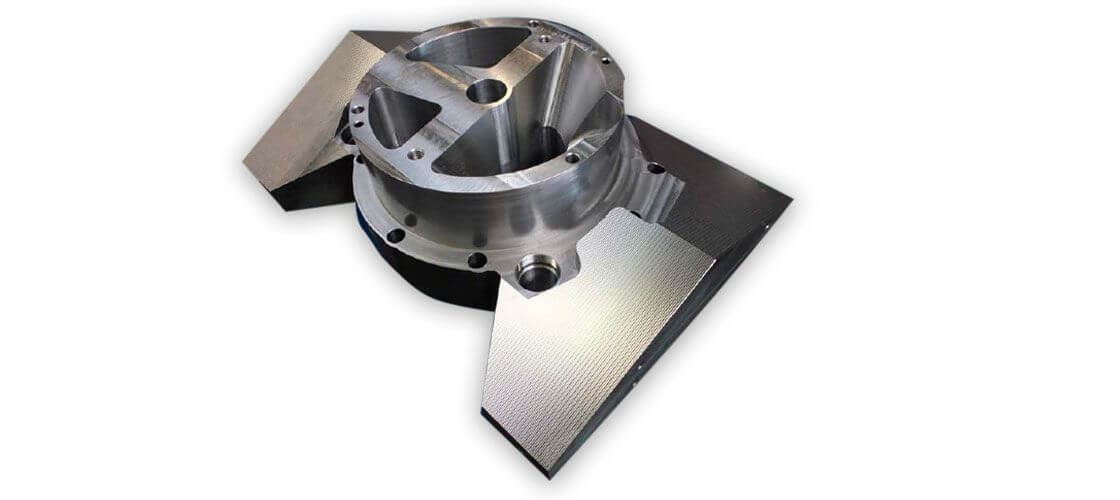

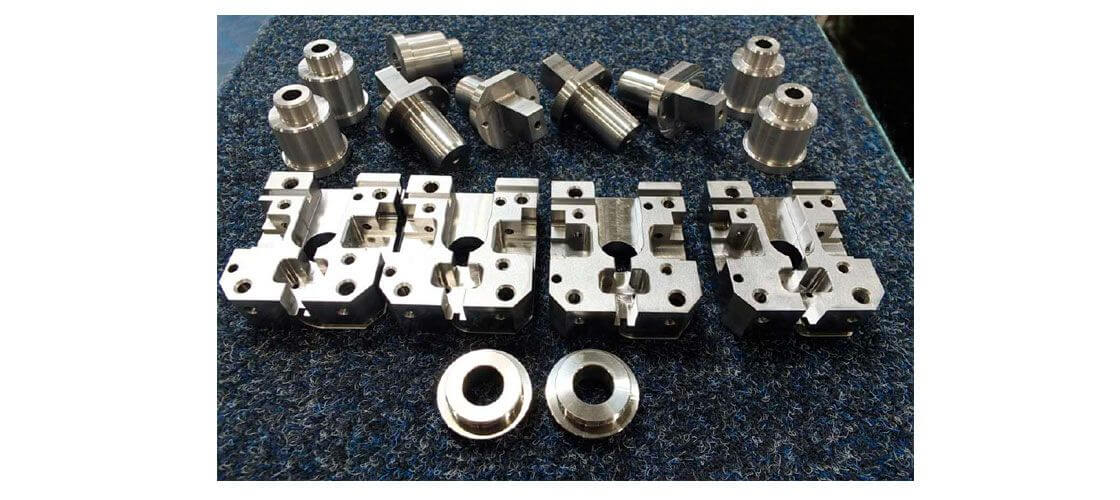

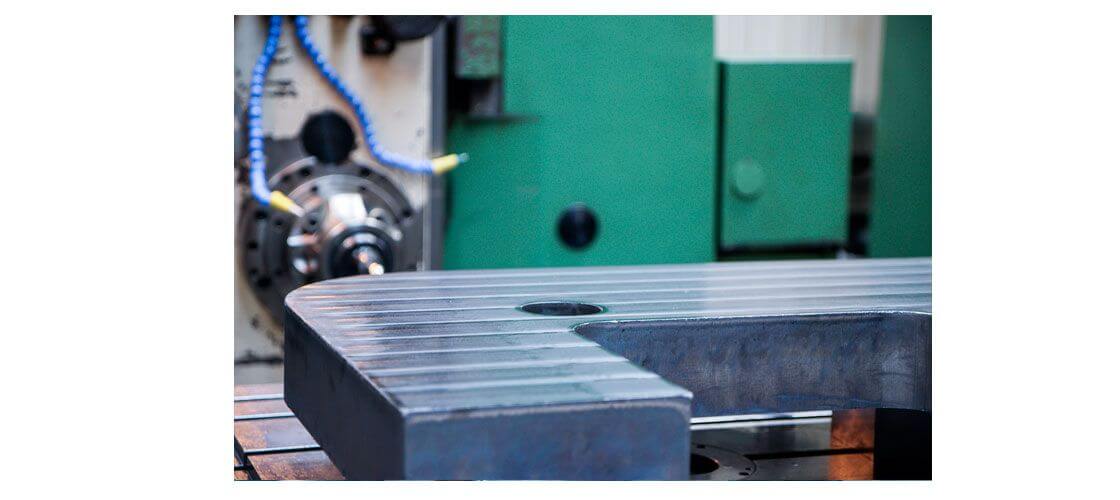

Machining, CNC milled parts for special machine builders

We are your competent partner for the machining production of complex CNC single parts in smaller quantities as well as with tight tolerances.

From sheet metal fabrication to turning and milling, we can provide the right parts for your project. Our CNC turning and milling technology enables us to manufacture drawing parts abd products according to your specifications.

We work with a machine park in CNC milling and CNC technology in our production facility in Pilsen, Czech Republic. This allows us to produce and manufacture precise milled parts for our customers as individual parts, small series or medium series. We process various materials such as steel, aluminum, copper, plastic to produce high quality components for you.

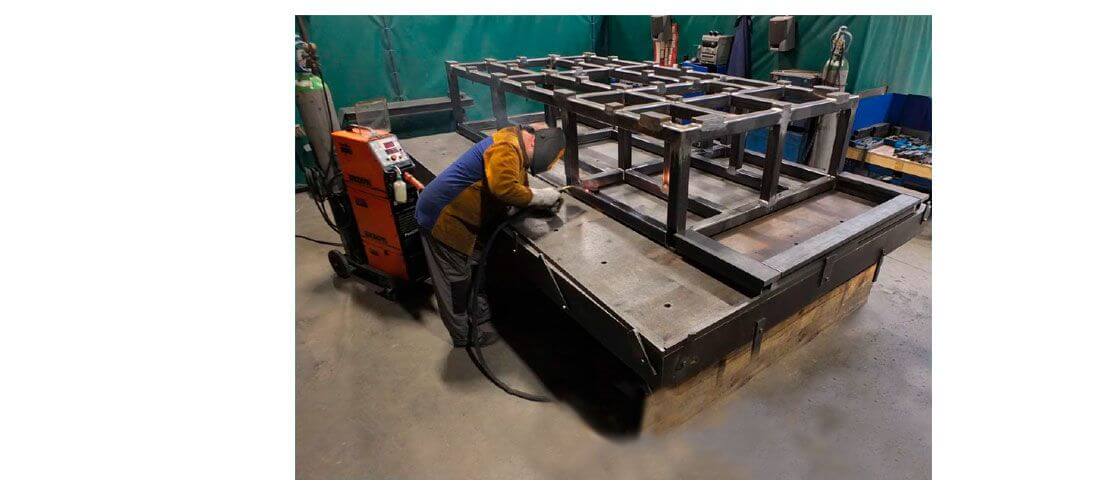

Welding of assemblies

Welding of assemblies is a separate production area in Pilsen. With the know-how of our experts, we guarantee that your welding work will always be of the highest quality. Our area for welding includes the TIG and MIG processes.

Our machinery - technical data

Production methods, machines and specifications for machining processing

Sheet metal processing bending

| max. dimension LxWxH | 3100x1450x2270 |

|---|

Pre-milling

| max. dimension LxWxH | 900x300x400 | |

|---|---|---|

| 1300x300x500 |

Milling machines, conventional

| max. dimension LxWxH | 190x290x340 | |

|---|---|---|

| 490x390x400 | ||

| 600X400X400 |

CNC turning, lathes

| max. dimension dxL | 200x800 | |

|---|---|---|

| 400x1000 |

CNC milling centers

| max. dimension LxWxH | 750x500x500 | |

|---|---|---|

| 800x500x550 | ||

| 1000x600x600 | ||

| 1500x1300x800 |

CNC horizontal milling center with rotary table

| max. dimension LxWxH | 1250x1100x940 | |

|---|---|---|

| 3500x2200x1800 |

Best results through close cooperation in surface treatment

Surface finishing is a complex subject area. Our network partners are therefore specialized in a wide range of surface treatments.

Through our cooperation with long-standing partners, we offer you a comprehensive range of services covering all relevant surface finishing processes. This allows us to offer you the optimal solution for your application area and support you in the implementation of your projects.

Surface treatments

- Painting - wet and powder

- Blackening

- Heat treatment - hardening, nitriding, carbonitriding, QPQ, Corr-I-Durr

- Galvanizing - Galvanized and hot-dip galvanized

- Chromating

- Nickel plating

- Anodizing and hard anodizing

- Titanium and plasma coating

We will be happy to advise you on your request

Our german-speaking customer service representatives are here for you to answer your inquiry quickly and effectively. Please send us your data directly by e-mail or via the contact form. We are looking forward to your inquiry!

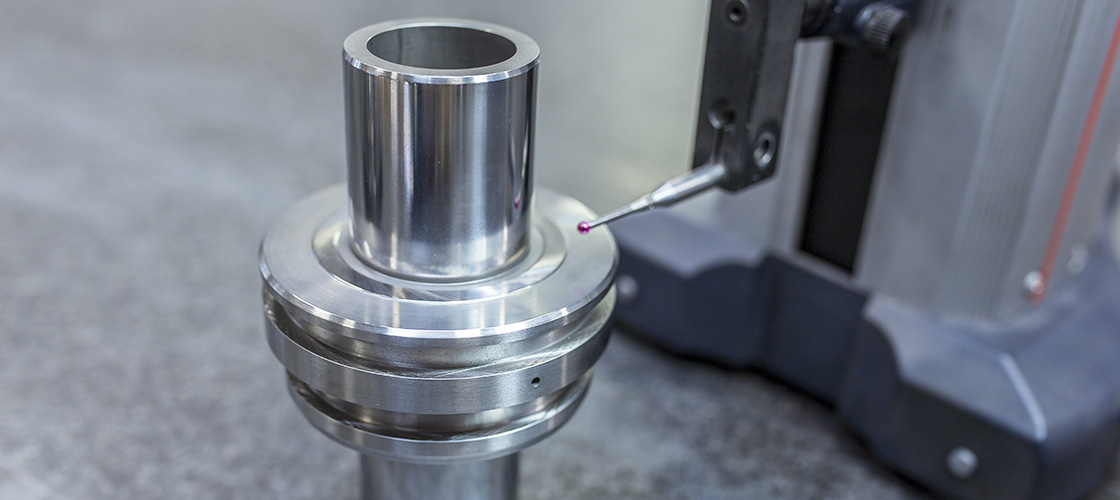

Quality assurance through certification

Our quality management is at the highest level. Through our certification according to ISO 9001 as well as the high manufacturing knowledge of our employees, we guarantee you the best quality.

References