Setting head for press tools

Automatic feeding and processing of fasteners under the press

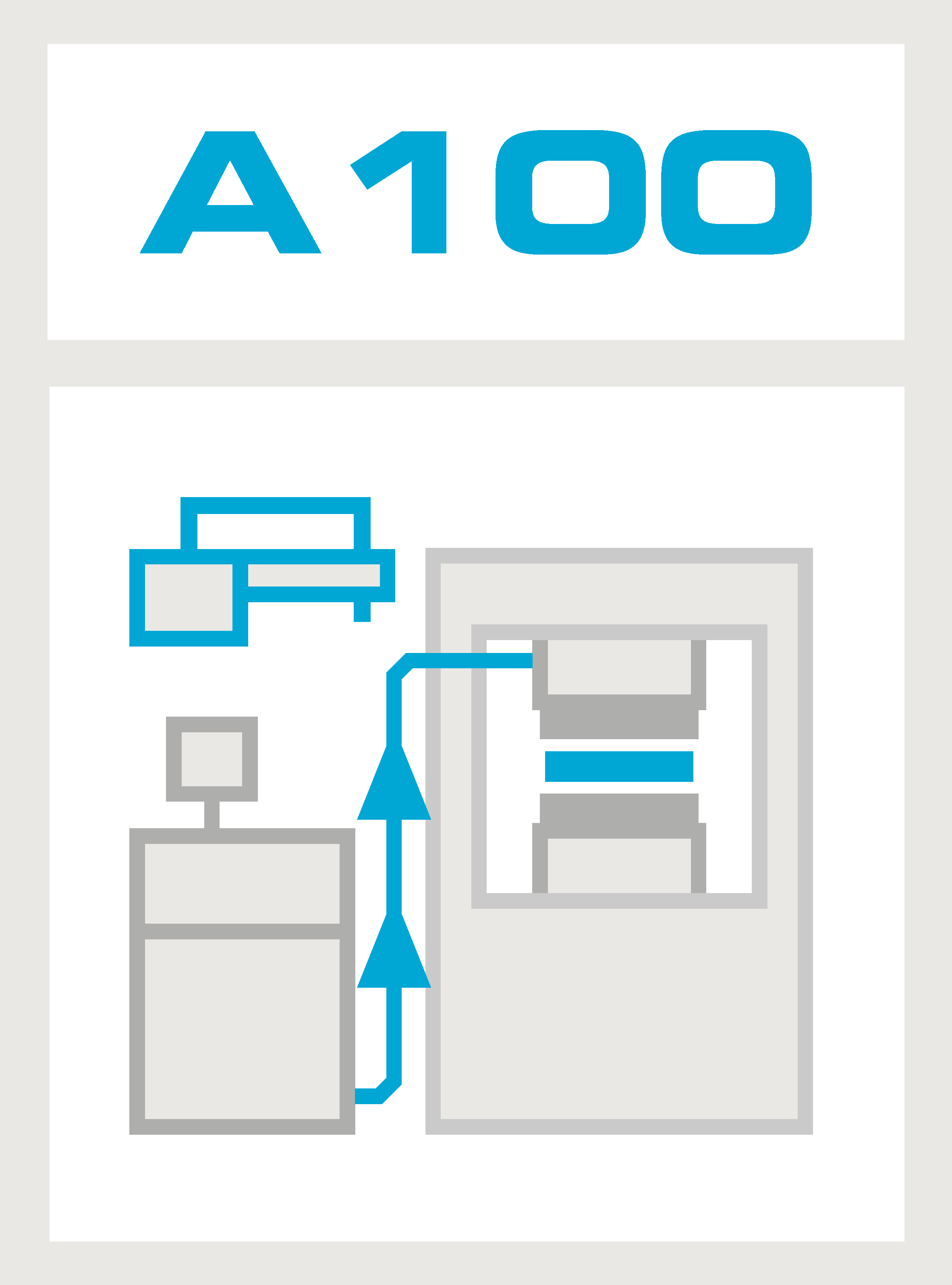

The A100 setting head is a fully automatic assembly system for for press tools like progressive dies and transfer dies. Finished parts can be produced directly under the press in punching and forming tools. This eliminates many downstream operations and the need for intermediate storage of components.

The automation system consists of these components:

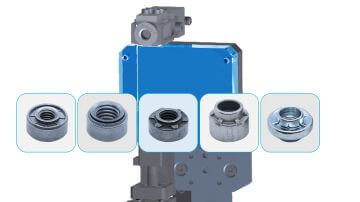

- Setting head for integration in the upper part or in the bottom part of the press tool

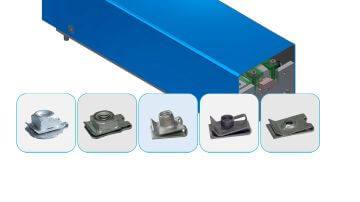

- Mobile feeding system with up to four shot hoses per conveyor unit, placed outside the tool

The punching head is available in several designs. Thus, different types of fasteners can be processed.

Customized solutions for your specific requirements are possible.

Advantages of the system

- Fully automatic, reliable processing of fasteners under the press

- Very short cycle time and good accessibility in the press

- Processing in thin sheets, thick sheets and plastics in one operation

- Flexible processing directions - from above, from below and in angular positions

- High degree of automation thanks to system technology from one company

- Process monitoring of the fasteners in the feeding system

Setting head A100 - Assembly system for press tools

Would you like us to call you back?

Please leave your phone number or email and we will get back to you as soon as possible!

You can also contact us at the phone number: +49 (0) 9416042-210

Contact us