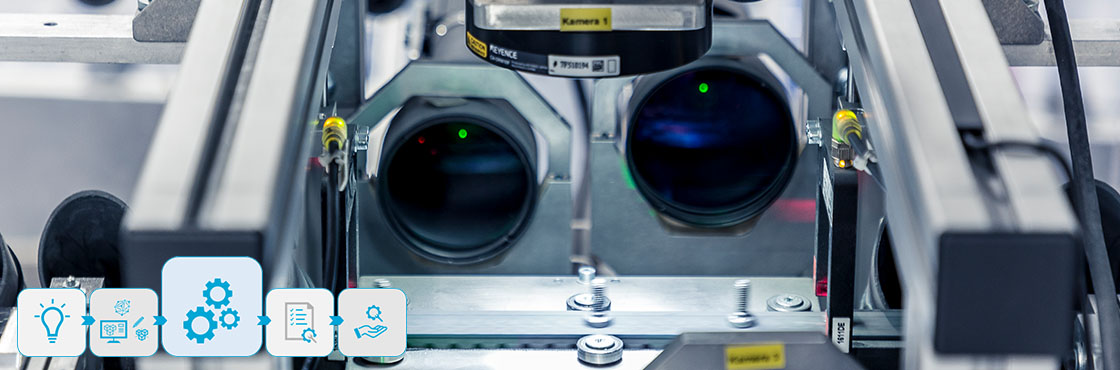

Optical sorting

100% vision inspection of fasteners

Using an optical sorting system, our fasteners are 100% visiually inspected before packaging. These inspections ensure that the fasteners are dimensionally stable and will function well in our equipment. Saving money by eliminating inspection will result in spending more money due to decreased reliability in production. This is the main reason why we prefer to offer both fasteners and automation as a complete system.

Through our 100% quality control with state-of-the-art testing methods, including digital measurements by high-resolution cameras and lasers as well as mechanical function tests, we guarantee you a smooth serial delivery which meets the highest quality standards.

Contact us

Our customer service will help you with any questions!