The BPR rivet ball stud has been developed to withstand extremely high loads and is set automatically with a setting head in a progressive die or transfer tool. Thus, the downstream operation for the orbital riveting of the ball stud is eliminated - with high cost savings as the result.

The BPR ball stud can also be set in very narrow sheets since it only requires minimum space. It is very similar to a standard ball stud but is a lot cheaper regarding the assembly.

Advantages of the BPR ball stud

- High cost savings

- Fully-automatic processing

- Geometry similar to standard

- Minimum space requirements

- Suitable for large sheet thickness ranges

- Customized geometries available

- Preservation of the sheet stability due to small pilot holes

Current state of the art technology for ball studs

There is a high number of ball studs in vehicles closure system. For example hinges of hoods and trunks. The following setting procedures are applied to fasten a ball stud in the bodywork:

- Orbital riveting of the ball stud with orbital riveting machines

- Welding of the ball stud by resistance welding

- Screwing the ball stud into a nut that has previously been welded or pressed into the sheet.

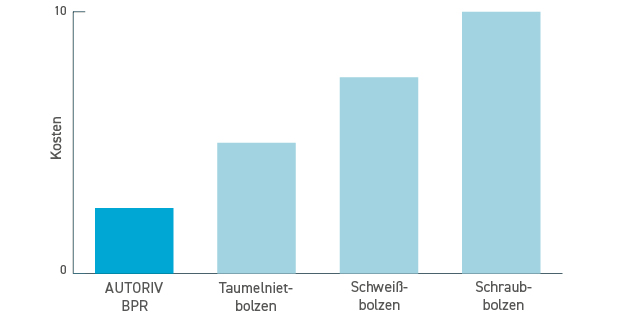

The prices are graduated according to the production costs and show that current setting procedures always come with a separate workstep.

The manufactoring of the bodywork thus requires another step which has a negative effect on the production costs due to expensive and elaborate automations.

Improvements on the current state of the art technology with BPR ball studs

BPR ball studs can already be inserted during the manufacturing of the body sheet metal. The downstream operation is thus completely eliminated. Thereby, high cost savings potentials arise for you:

- Reduced logistics costs due to the elimination of in-plant transportation in between the production stages

- Reduced staff- and salary costs due to the elimination of a downstream operation

- Low space requirements (because no downstream system is required)

- Shorter processing times and thus, lower capital commitment and lower warehousing

Exemplary costs for the assembly of sheet metal parts with ball studs

Advantages of the BPR ball stud overall system

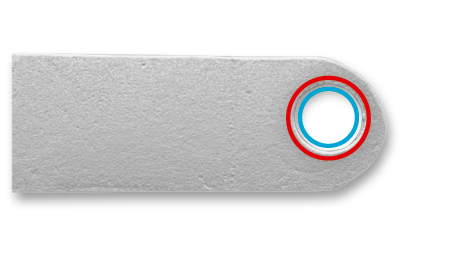

Low space requirements

The BPR ball stud can be inserted very closely to border areas. Only the diameter of the base is required as space. Thereby, it can also be inserted in very narrow sheet metals.

BPR ball stud (blue)

head diameter 10 mm

base diameter 13 mm

space requirement 13 mm

Ball stud competitors (red)

head diameter 10 mm

base diameter 14 mm

space requirement 20 mm

No indentation when riveting

Due to the special rivet geometry of the stud, the sheet is not deformed during the riveting. Thereby, the danger of indentations in border areas is eliminated.

BPR ball stud (blue)

No indentation

Ball stud competitors (red)

Indentation when riveting close to the edge or narrow sheets

Preservation of the sheet stability

The BPR ball stud only requires a small pilot hole in the sheet to be inserted. Thereby, the stability of the sheet is affected as little as possible.

BPR ball stud (blue)

Pilot hole diameter 5,8 mm

Ball stud competitors (red)

Pilot hole diameter 8,7 mm

High sheet thickness ranges

AUTORIV ball studs can be inserted into thin sheets (1 mm) as well as into thick sheets (5 mm). However, the stability of the sheet must be sufficient for the load to be borne by the stud.

Quick developments of special applications

If you have to realize special requirements in your application, we can rather quickly (within approx. 3 weeks) present you a customized ball stud that meets your requirements and can perform test series with it. The automatic processing system for such special elements can also be manufactured within the standard delivery time.

Geometry similar to standard

The geometry of the AUTORIV ball stud is very similar to the standard ball stud. For you as a developer or user, it is thus significantly easier to switch to our ball stud and to thereby save costs in your company.