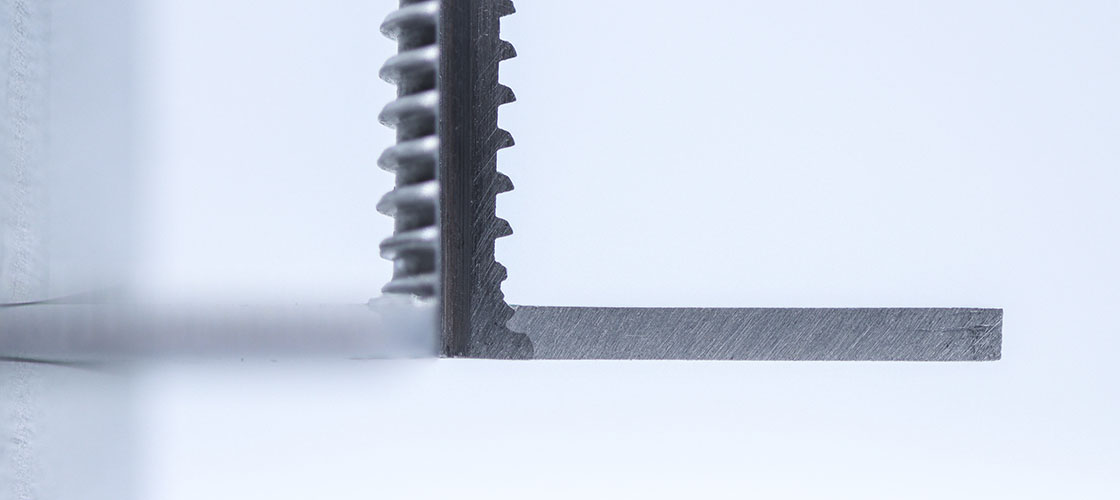

SHS countersunk clinch stud

for automated feeding and processing

Countersunk clinch stud / screw set flush without sheet metal protrusion. For particular applications when the screw head should not extend beyond the sheet metal surface. In use at car manufacturer OEMs in Germany, Europe and the USA. Widely used at Tier1 level.

Sheet thickness - Used for metal sheets with thicknesses from 1.5mm upwards without limitation

Thread size - M5, M6, M8, M10, M12

Workpiece material - Steel, aluminum, copper, magnesium

Outer diameter - Small

Pull-through force - Low

Torque - High

Push-out force - Medium

| Thread (d2) | Head diameter in mm (d1) | Collar height in mm (l3) | Min. sheet thickness in mm (s) | Polot hole diameter in mm (Ø -0.1) | Thread length in mm (l2) |

|---|---|---|---|---|---|

| M5 | 6.50 | 2.70 | 1.50 | 5.15 | 8 / 10 / 12 / 15 / 18 / 20 / 22 / 25 / 28 / 30 / 35 /38 |

| M6 | 8.20 | 2.70 | 1.50 | 6.15 | 10 / 12 / 15 / 18 / 20 / 22 / 25 / 28 / 30 / 35 / 38 |

| M8 | 9.60 | 2.70 | 1.50 | 8.15 | 12 / 15 / 18 / 20 / 22 / 25 / 28 / 30 / 35 / 38 |

Tolerances according to ISO 2768-m.

| Thread | Material | Sheet thickness (mm) | Press-in force (kN) | Push out force (kN) | Torsional strength (Nm) |

|---|---|---|---|---|---|

| M5 | Aluminum | 1.60 | 24.50 | 1.07 | 3.50 |

| M5 | Steel | 1.50 | 33.40 | 2.00 | 6.50 |

| M6 | Aluminum | 2.40 | 28.90 | 1.66 | 7.33 |

| M6 | Steel | 2.20 | 44.50 | 2.56 | 11.30 |

| M8 | Aluminum | 2.40 | 29.80 | 1.91 | 11.30 |

| M8 | Steel | 2.40 | 44.50 | 2.89 | 19.20 |

These values are for orientation only and are not binding.

Tests were conducted in steel H320 LA and aluminum EN AW-5754.

| Thread proof load | Thread length | Thread ends | Thread tolerance | Thread coating as an option | Surface protection |

|---|---|---|---|---|---|

| according to class 8.8, 9.8, 10.9 possible | according to customer requirements | according to standard, as well as MaThread | 6g, 6h | Nycote, Precote | Various surface coatings possible |

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!

Application and function

Suitable for: Insertion in metal sheets with tensile strength less than 600N/mm². It can be used in galvanized, painted metal sheets

Sheet metal bottom: Flat without indentation

Pilot hole preparation: Pre-punched pilot hole according to AUTORIV specifications

Die: Use of a flat die (optimal downtimes)

Installation: Torque absorbers and screw head move and shape the material into the collar undercut

Outer diameter - pull through force: Small head diameter, flush press-in of the head into the sheet is possible without head protrusion, low pull through forces

Under-head serration - torque: Strong under-head ribs for high torque absorption

Collar - push out force: Collar with undercut to provide push out forces

Highlights

- Lighter C-frame on the robot

- Larger projections / overhangs possible

- Shorter cycle times

- Pressing into undercuts or profiles is easier to handle than with other fasteners

Lower risk of warping of workpieces, especially with many setting positions

- Lower risk of warping of work pieces

- Flat sheet metal bottom with largest surface possible for the preload through tightening

Customized solutions for sheet thicknesses less than 2mm possible

- No diversity, less stock requirement

- No risk of mix-up (Incorrect fasteners in incorrect application)

- (Re-)use of existing automation / tooling, thus reduction of investment

Greater compensation possible with custom design, possible with suitable AUTORIV thread end

- Ensuring optimal pressing: No "Not-OK pressings" with risk of subsequent complaints and quality costs

- No frequent re-teaching of the robot necessary

- Ensuring high availability and output, thus cost reduction

- Setting in limited installation spaces is possible

- The head does not extend beyond the sheet metal surface. Countersunk head sinks completely into the sheet metal