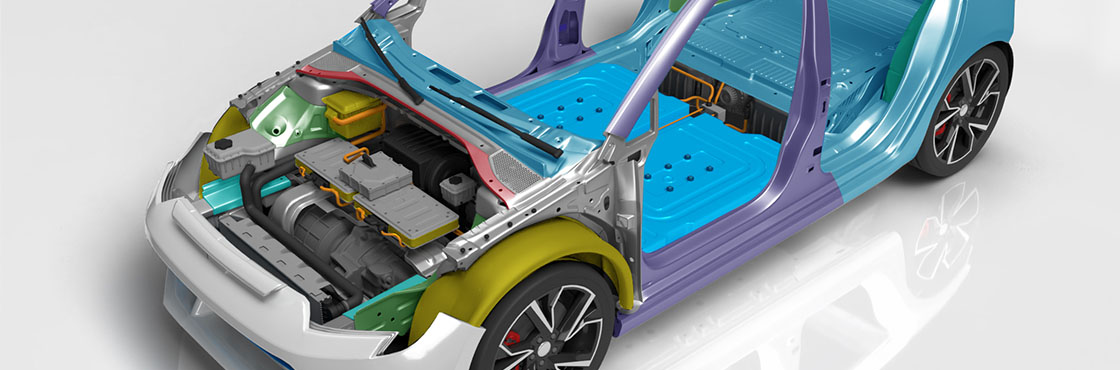

Lightweight solutions

Suitable fasteners for all requirements in lightweight construction

Without innovative joining technology, lightweight constructions are hardly feasible. In the realization of lightweight construction concepts, the challenge lies in the development of suitable fasteners for each base material.

For example, fasteners for aluminum applications require larger contact surfaces and are initially more massive in design to compensate for the lower inherent stability.

With our many years of experience and know-how, we will be happy to support you in selecting the right fastener for your application and automating it in combination with the suitable joining process.

Contact us

Our customer service will help you with any questions!

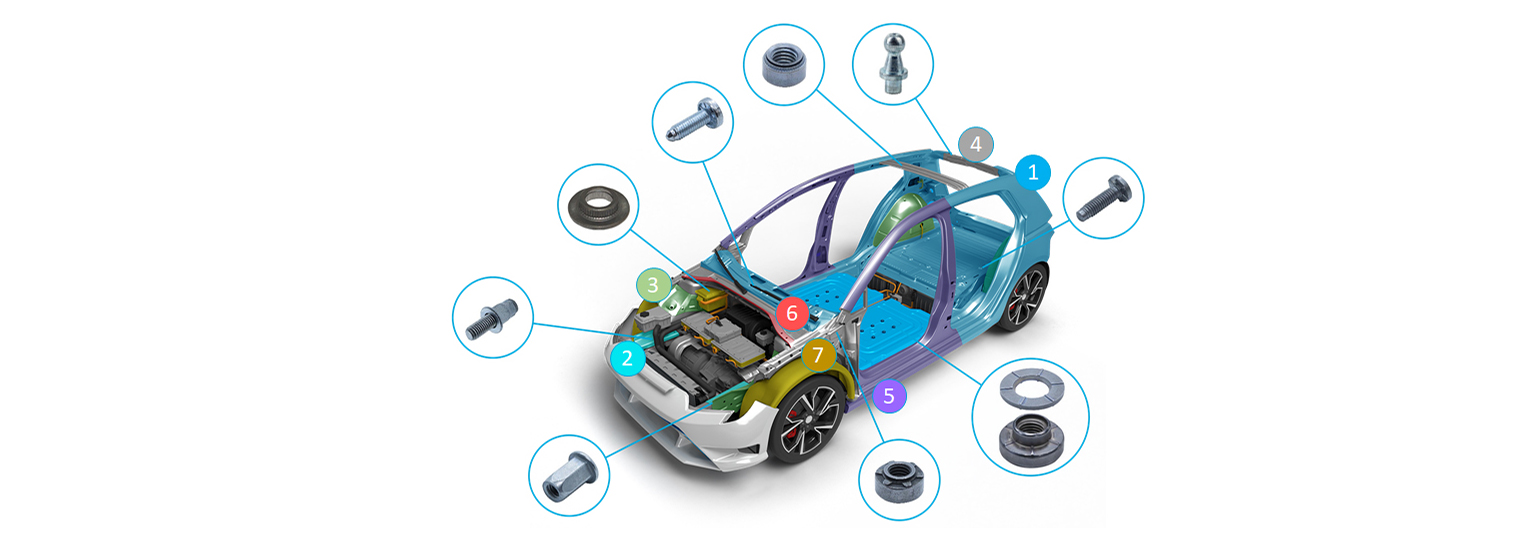

1. Aluminum sheet

2. Aluminum profile

3. Aluminum cast

4. Conventional steel

5. Ultra high strength steel

6. Magnesium

7. Plastic / fiber composite

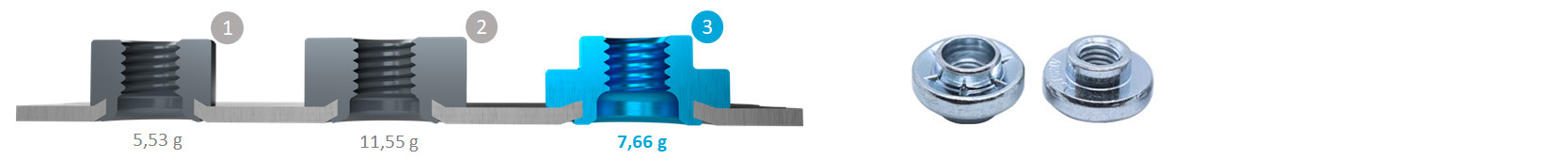

Steel and aluminum sheets from 0.7mm

Rivet nut with oversized contact surface and simultaneous weight optimization

- Lightweight, but only small contact surface

- Large contact surface, but high weight

- Example ATR rivet nut, M8 - Optimal contact surface and 33% weight saving

Advantages of the ATR rivet nut

- Less weight per vehicle and lower cost per fastener

- High performance in terms of push-out forces, pull-through forces and torques

- The rivet nut can be used in large sheet thickness ranges without the need to change the fastener, thus reducing the number of variants

- Push-out force [N]

- Torque [Nm]

Advantages of the STN clinch stud

- Far above-average performance compared to standard clinch studs

- Optimum quality data with regard to push-out forces and torques

- Can be used in very large sheet thickness ranges without changing the fastener - One solution instead of many variants

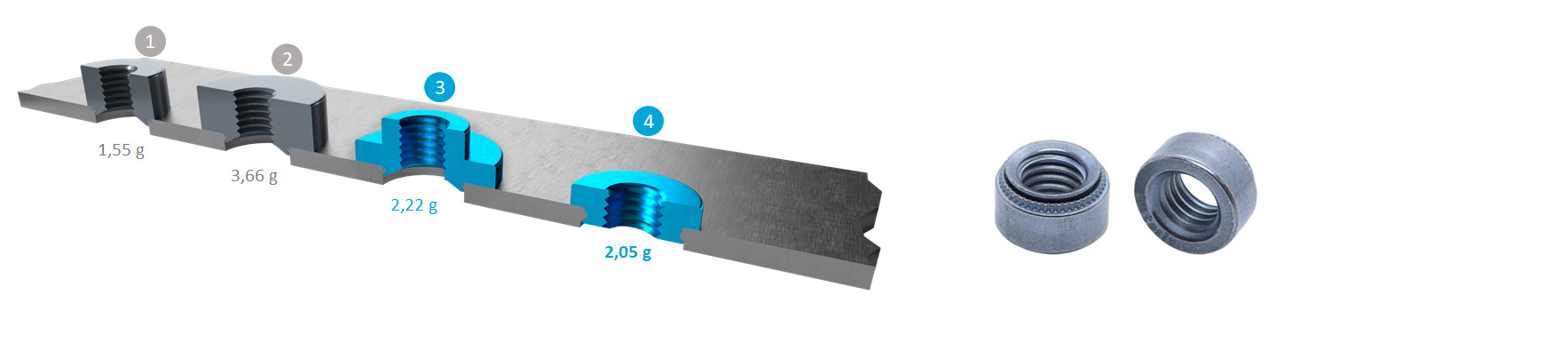

Steel and aluminum sheets from 2mm

- Lightweight, but only small contact surface

- Large contact surface, but high weight

- Example ATR rivet nut, M6 - Already weight-optimized with optimum contact surface

- Example ASN clinch nut, M6 - Optimum contact surface and even greater weight savings due to displaced thread components

Advantages of the ASN clinch nut

- Oversized contact surface and high performance with simultaneous weight optimization, as load-bearing thread components are displaced into the sheet thickness

- Less weight per vehicle and lower cost per fastener

- Self-piercing versions also available - STN clinch nut / self-piercing nut

- Oversized contact surface for better performance

- Can be used in large range of sheet thicknesses without the need to modify the fastener

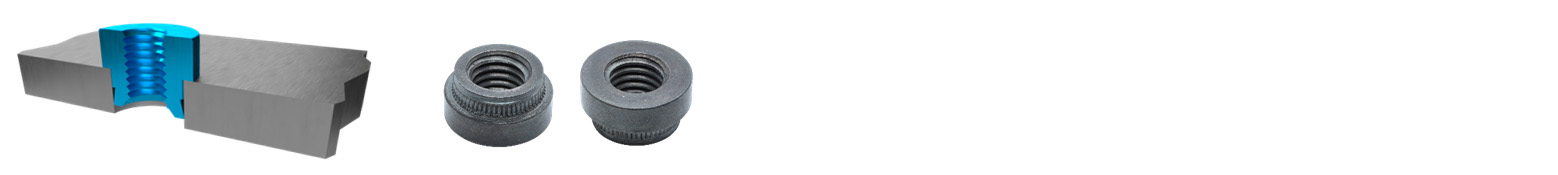

Aluminum and magnesium sheets from 3mm

- Clinch studs for use in very thick sheet metal - in aluminum and magnesium die castings

- Minimal material displacement during the clinching process to avoid crack initiation

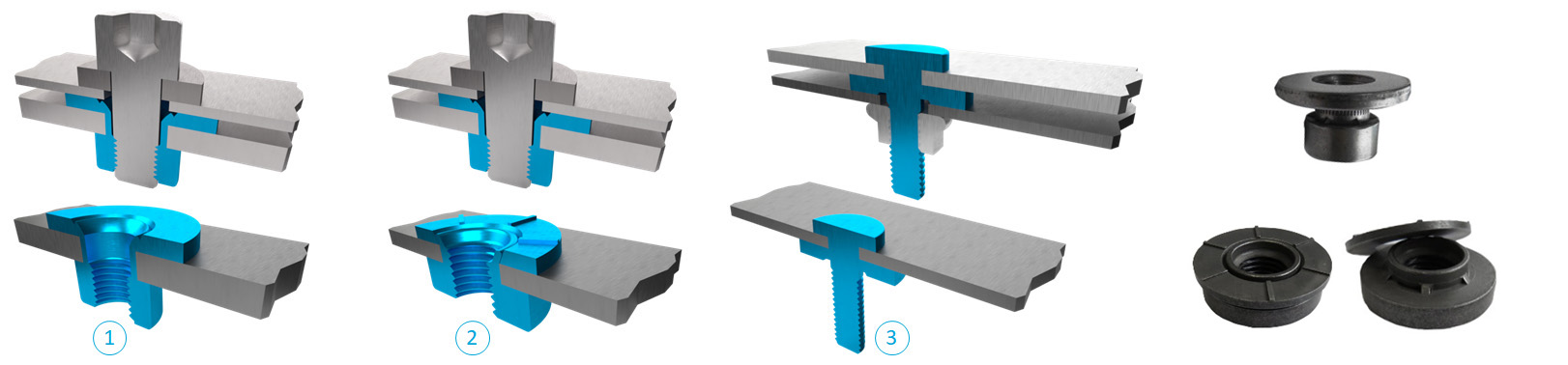

Self-piercing nuts

- For brittle materials and very thick sheet metal

- To avoid crack initiation, fasteners should hardly displace material in brittle structures

- Pilot hole preparation causes additional costs, which can be reduced by using self-piercing fasteners

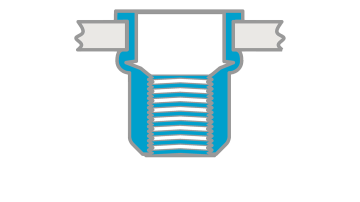

Thread inserts without tapping

Higher load capacity of threads in brittle materials and lower tool wear compared to helicoil inserts, which require drilling first and then cutting.

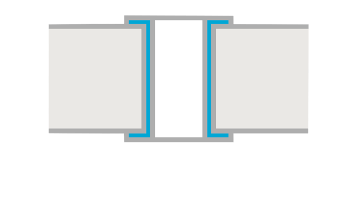

Insulators and spacers

Insulators for chemical separation and spacers, e.g. between steel and aluminum, provide high structural strength and protection against corrosion through ZnNI coatings while being economical.

- Combination of rivet nut and spacer without ribs

- Spacer with ribs for additional positive locking for lateral transverse loads, e.g. for crash management systems (CMS)

- All advantages of this combination also available as stud version

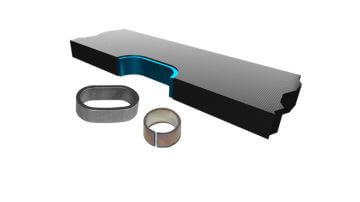

Plastic and carbon fiber

Reinforcing bushing as hole reinforcement to prevent crack initiation or deformation of the material, especially in soft materials such as carbon fiber. Available in oval and round design.

Large diameter spacer for optimum force distribution on both sides to prevent crack initiation, damage and deformation.

- Blind rivet fasteners according to the latest standards - Can be set stationary or in-die

- Wide range of standardized blind rivet nuts and studs

- Also available as special custom designs