System solutions

Optimal combination of fastener and automation technology for best possible results

Find out more about our system solutions: What fastener automation means to us and how we can support you in the realization of your project. Also get an overview of automation combinations of joining processes, fasteners and technology.

Contact us

Our customer service will help you with any questions!

"Precision is the foundation for high-performance products at MDS."

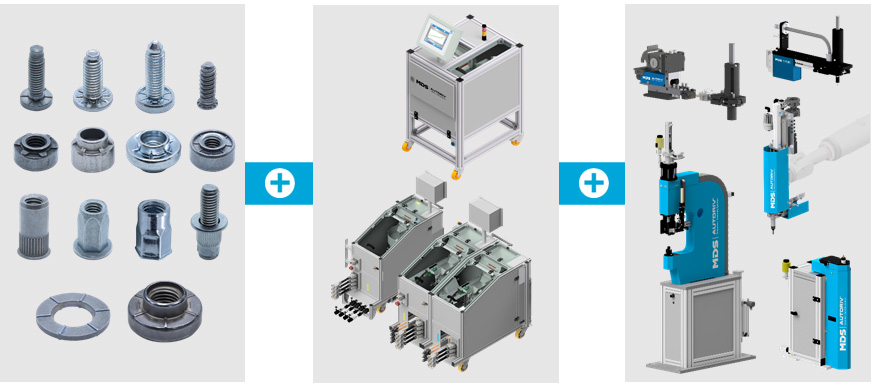

Our system solution

Our system solution is a complete system of automation grade fasteners and automation technology, matched with each other exactly. We develop the fastener together with the automation technology. This means that we exclude all potential difficulties in feasibility from the beginning.

In order to achieve the best possible result, we provide you with the right fastener and a perfectly matched automation solution, seamless process monitoring, comprehensive documentation, and complete traceability.

Your benefits:

- Guaranteed process-reliable and economical automation of fasteners

- Time savings and reduced risk due to reliable applicability

- Effective utilization of all cost reduction potentials due to high vertical integration

- Our established, series-proven modular system ensures short development times and high availability

- High production output and high quality of the end product

Application example

Manufacturing of an instrument panel carrier for an OEM platform

We provide the following components for the manufacturing of the instrument panel carrier:

- Clinch fasteners and special designed fasteners

- Automation modules - feeders and setting heads

The fasteners are automatically fed and assembled in-die in a single-stage process.

- Transfer-die modules for automated assembly of nuts and spacers

- Turn-key final assembly equipment for the assembly of the instrument panel carrier. The process includes full process monitoring, complete documentation and traceability.

The system is currently used in six countries in North America, Europe and Asia.

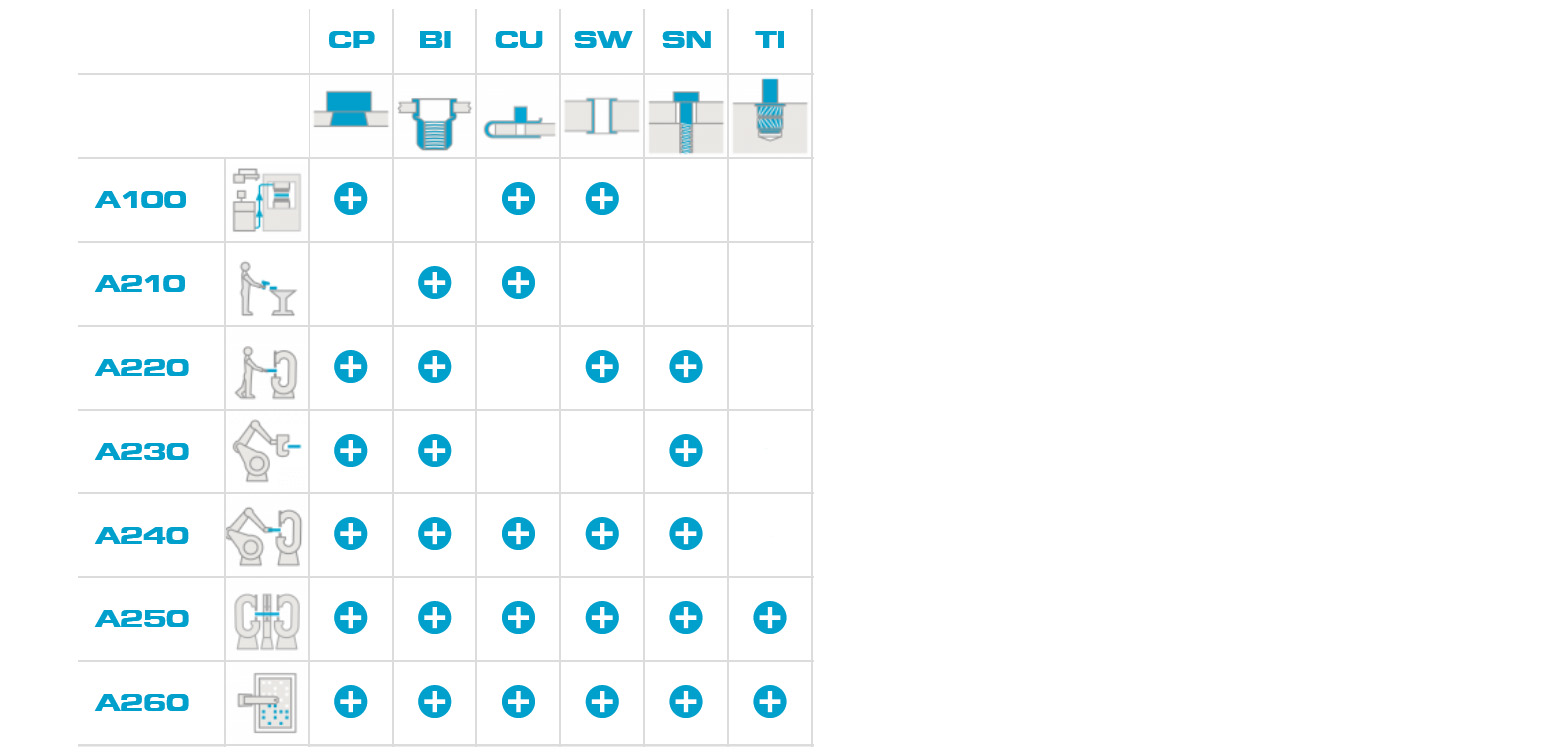

Combinations

Find your ideal combination of joining process, fastener and automation technology