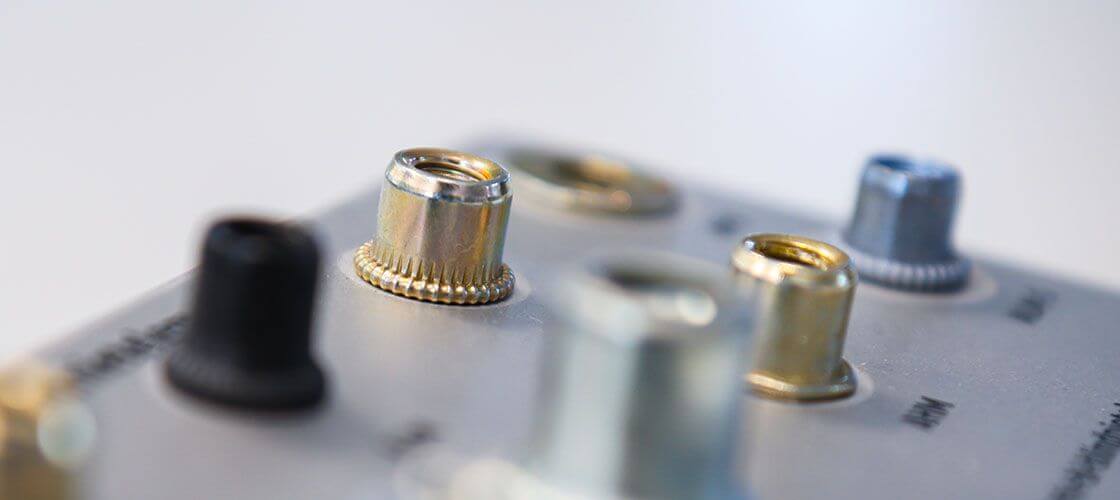

Spin-pull riveting

Blind rivet fasteners are installed by axial pulling force.

In spin-pull riveting as a joining process, the blind rivet fastener is screwed on a thread and inserted into the pilot hole before the installation process. Subsequently, the blind rivet fastener is exposed to pulling force via thread. This results in deformation of the blind rivet bulge on the rear side of the metal sheet. A form-fit joint between the blind rivet fastener and the part is created.

With the completion of this process, the pulling mandrel is spinning out. The assembly position only has to be accessible from one side. The part should have a corresponding pilot hole.

However, blind rivet nuts with the highest property class do not necessarily meet the expected strength requirements for the subsequent screw joint. In such cases, clinch nuts or rivet nuts, in combination with a washer or spacer if necessary, provide the better solution for high-strength structural connections.