Pressing and clinching

Fasteners are pressed into a component with high axial power.

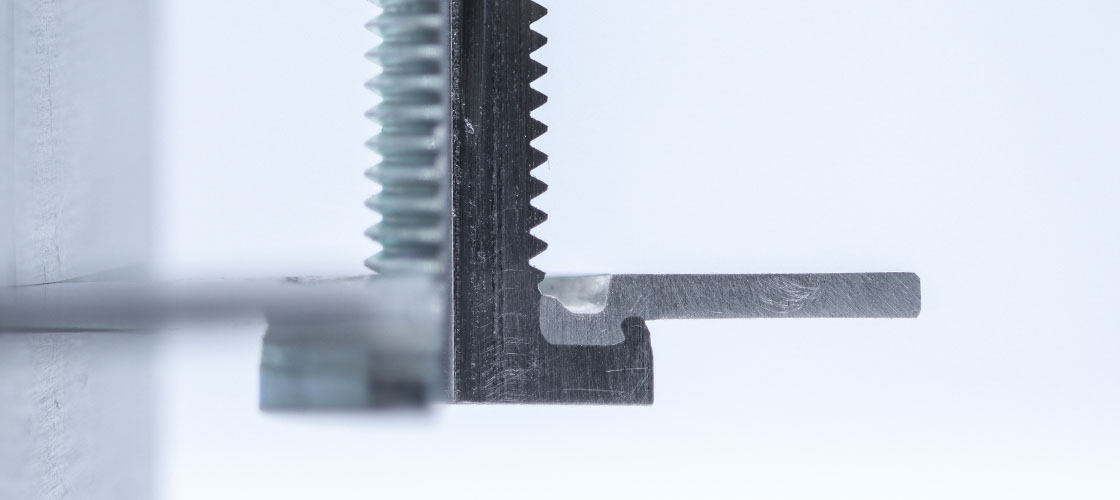

Within the joining process of clinching and pressing there is a basic distinction between clinching and self-piercing fasteners. While clinching fasteners are pressed into a pre-drilled component, this process is not necessary for self-piercing fasteners. A slug is formed during the setting process. In both cases, the component instead of the fastener will be deformed (in opposition to the fastening process with rivet nuts). The material of the component merges with indentations on the fastener, which leads to a tight fit. Thereby, it is possible to achieve high push-out and high torque.