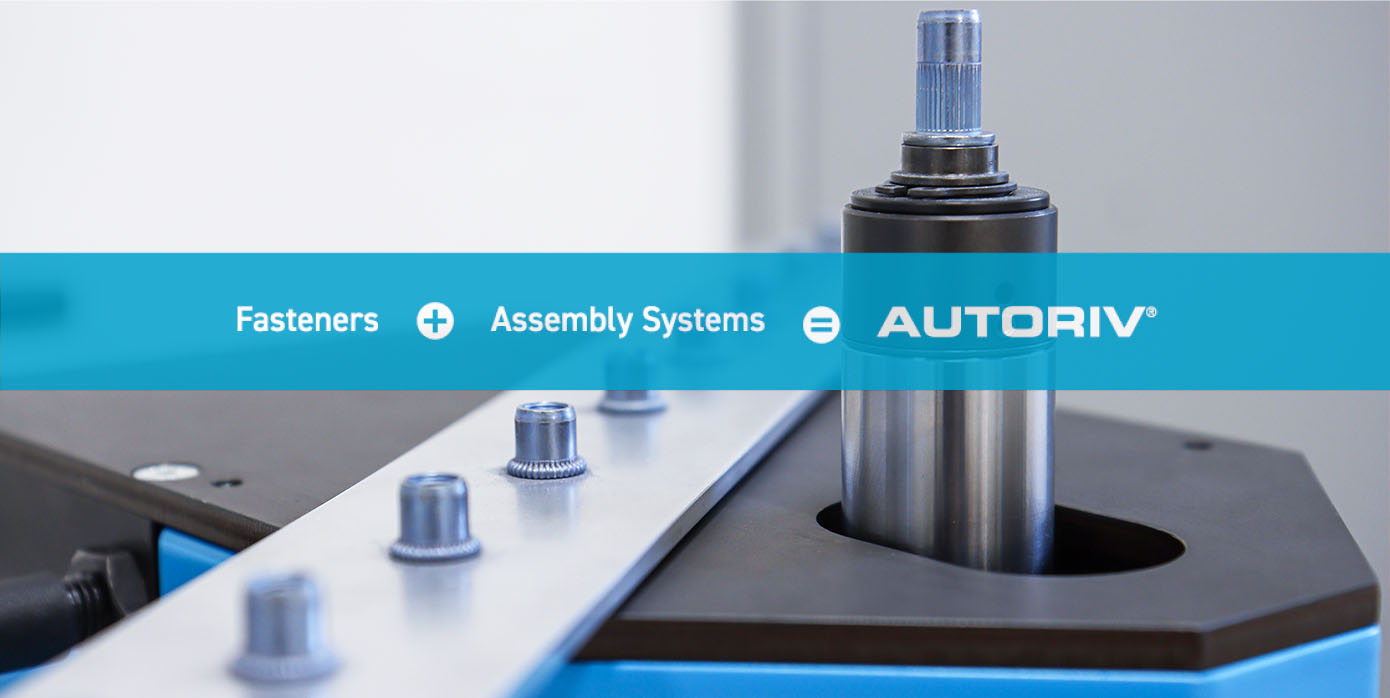

Your system supplier

50 years of automated fastening technology

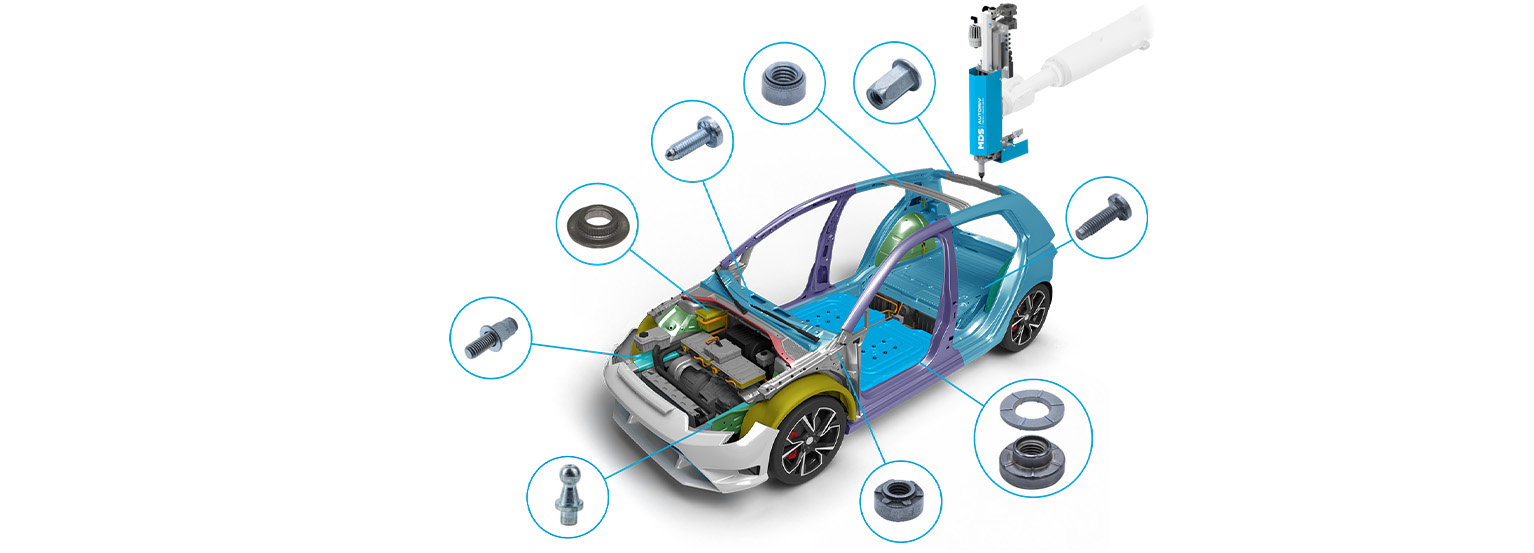

We are the only system supplier that has its roots in automation technology and not in the manufacturing of fasteners.

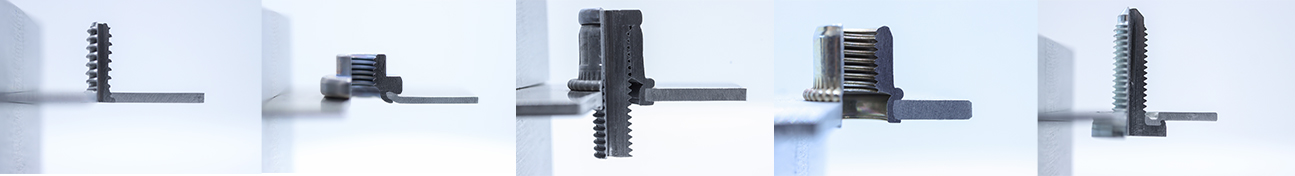

Due to many years of experience as a toolmaker, we have very large development capacities and detailed know-how in the fields of: Fasteners and automation, feeding technology, toolmaking up to special mechanical engineering.

Contact us

Our customer service will help you with any questions!