More than one joining process

Various cold joining processes combined in an automated application

We offer more than just one single joining process. We provide you with various cold joining processes such as clinching, riveting, spin-pull process and others. With our long-term experience in cold joining technology we are at your side if you want to combine several processes in one automated application.

Contact us

Our customer service will help you with any questions!

Multiple joining processes in one application

Complex assemblies generally require the use of more than one fastening method. Different types of fasteners such as clinch nuts, blind rivet nuts and thus more than one joining technique are often required in a single application.

It is common for these different technologies to be sourced from several suppliers. The reason for this is that there are not many suppliers who are proficient in more than one joining process. In most cases, a supplier only specializes in one particular field. By contrast, we have several different cold joining processes in our range, which we can bring together in your application.

Your benefits

- Know-how in multiple joining processes

- Objective advice and optimal selection of the most fitting joining process

- Faster development and planning processes

- Optimally coordinated, fast and reliable processes

- Cost savings in investment and in subsequent production

Application example

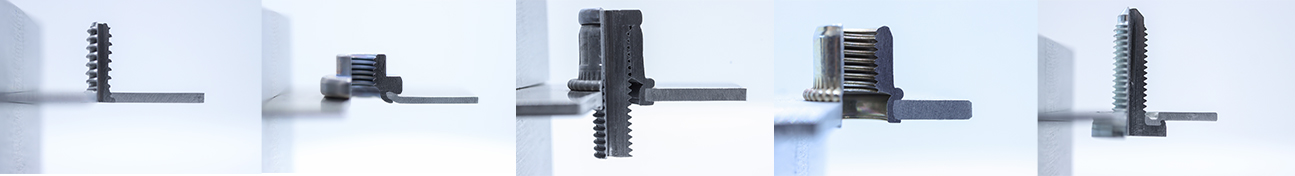

Manufacture of a magnesium die-cast reinforcement for a trunk lid

In this automation process we use the joining methods spin-pull riveting, blind riveting and bolting. The assembly takes place in a fully automated robotic cell with the following operations:

Spin-pull riveting of 18 blind rivet nuts in M5, M6, M8.

Spin-pull riveting of 2 blind rivet studs as ground screws

Spin-pull riveting of the ground nut

Automatic feeding and riveting of sheet metal components using 6 breakstem rivets

All components are automatically fed and assembled. The installation process is fully monitored and documented. All automation units are from us, with the exception of the robot. The entire robotic system was developed and built in-house.