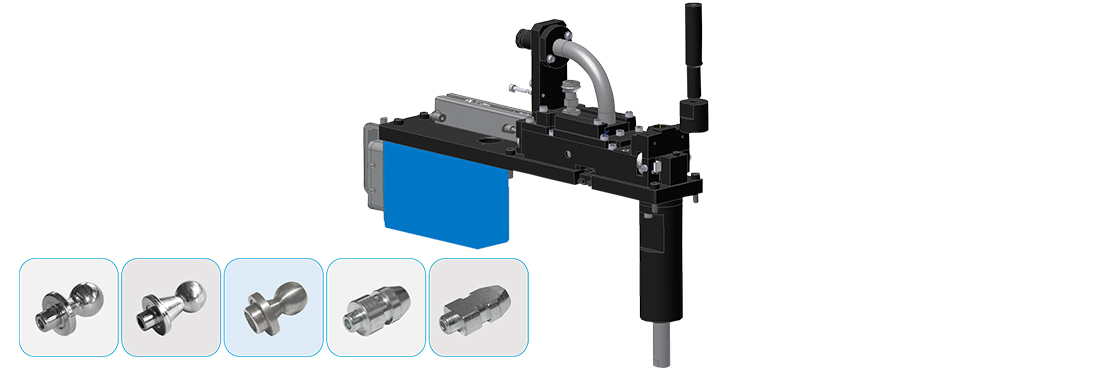

Setting head for ball pin studs, rivet studs, self-piercing studs

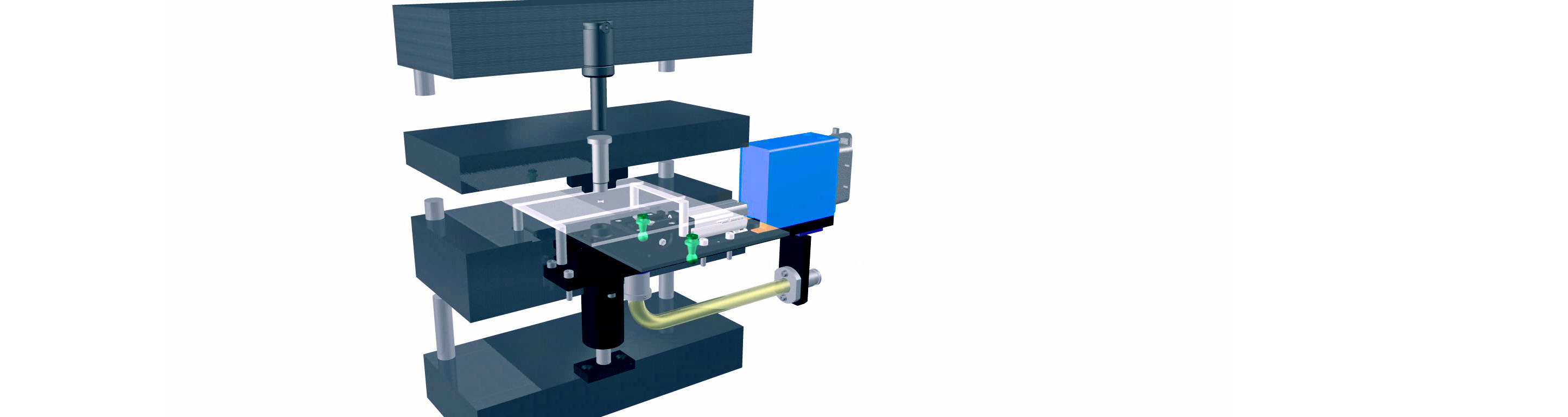

Installation under the press in punching and forming tools

The setting head BPR (Ball Pin Rivet) is an assembly system for progressive dies and transfer dies. The punching head is installed in the press to insert ball pin rivets, self-piercing studs, rivet studs and other bolt-type fasteners into sheet metal parts during the press process.

Depending on the type of tool and the press, there are different applications for the punching head

- Progressive dies with or without automatic mode signal from the press

- Transfer dies, with or without automatic mode signal from the press and with querying sheet metal in the die or in the gripper

Contact us

Our customer service will help you with any questions!

Installation and processing

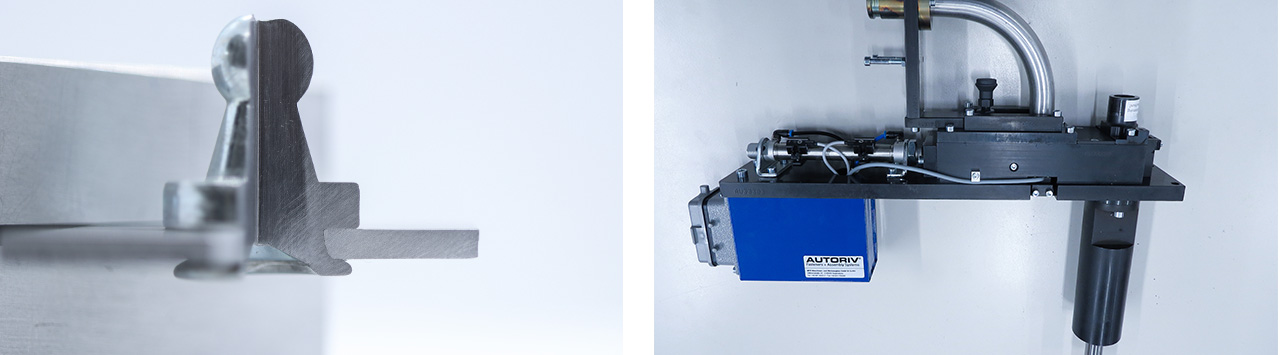

The setting head processes stud and screw fasteners that are pressed in with the head first. Typically, ball pin rivet studs are inserted into the workpiece from the bottom and riveted from the top. A custom configuration with top-down operation is possible.

The punching head is placed in the bottom of the tool or in the spring base. The ball rivet stud is inserted into the pilot hole by the relative movement of the spring base.

Function

Setting process

The setting head is connected to the associated feeding system for press applications and is supplied with ball rivet studs through a shot hose. The fasteners are transported by a pneumatic cylinder. When a ball rivet stud is in the setting position, a release signal is sent to the press. Without a release signal, the press stops. In all positions in the punching head, there is a direct query of the ball rivet studs.

Main process

The main process co-ordinates the part request to the feeding system. It ensures that the ball pin rivet studs are moved to the setting position on time and monitors the press strokes by interrogating the press cams.

Pressing

The ball rivet stud is pressed into a sheet metal part from the setting position by the press-in mandrel. The ball rivet stud is surrounded by the plunger to ensure a proper fit in the component. If no workpiece is present during a press stroke, no ball rivet stud is moved to the setting position. The plunger remains at top dead center due to blank sensing. An idle stroke is performed.

Air supply

A pneumatic connection on the feed system transfers compressed air to the setting head. This connection supplies the permanent air, the pneumatic cylinder for the slider and, optionally, the press-in mandrel.

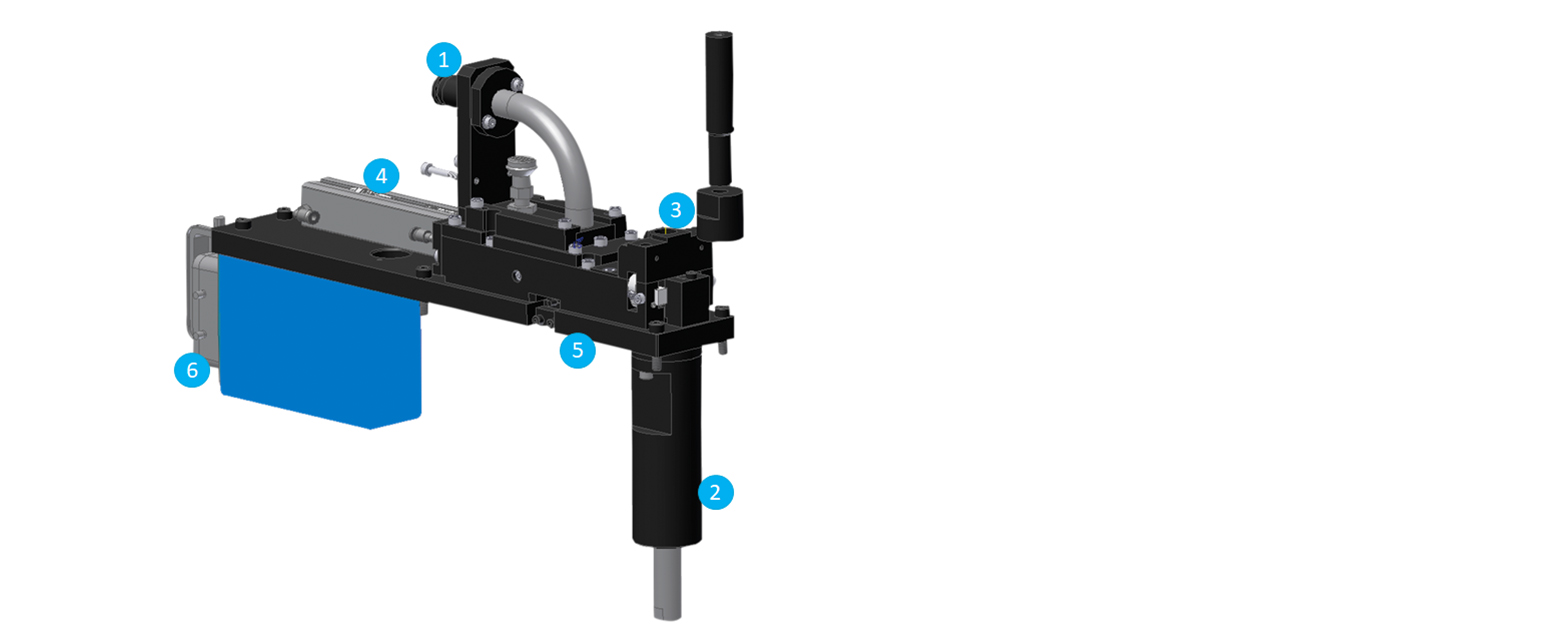

Components

Connector plug (1)

The connector plug is used to connect the shot tube to the setting head. The coupling is held in place by a locking pin on the connector plug of the punching head. The ball pin rivet stud is transported via the screw feed (bent tube) into the screw transport.

Plunger (2)

The plunger houses the press-in mandrel, which presses the ball rivet studs into the sheet metal component. The mandrel is actuated by closing the press and transmits the compression force to the fastener. When the press is opened, the mandrel is pneumatically returned to the home position.

Impact piece (3)

The impact piece guides the ball rivet stud during the press-in process.

Feed cylinder (4)

The setting head has no accumulation path. The ball rivet studs are shot directly into the grippers of the screw transport.

Screw transport (5)

The screw transport picks up the fed ball rivet stud and conveys it to the setting position.

Multifunctional hose connection (6)

All signals are transmitted from the setting head to the feeding system via the multifunctional hose. The multifunctional hose also provides pneumatic supply to the punching head.

Highlights

High production reliability and quality

All important functions in the setting head are sensor-monitored with communication to the feeding system to stop the press in case of a malfunction well before top dead center (TDC) and thus avoid die damage.

Fast stroke rates

If a ball rivet stud is in the setting position and still being processed, the next ball rivet stud can already be reloaded. The next fastener can therefore be shot into the setting head in parallel with the processing of one fastener. This means that higher processing speeds can be achieved even with long shot hose lengths.

Safety during coil changes and with empty parts in production (transfer dies)

The feed cylinder only moves to the setting position when a ball rivet stud is to be installed. Transfer die: If there is no workpiece, the feed cylinder does not move to the setting position. It moves when a workpiece is present. The empty part sensor is either in the transfer grippers or in the tool itself. Coil change: When a coil change is required, the feed cylinder remains in the home position and the coil can be retracted as if there were no setting head installed in the tool.

Quick commissioning

The setting head has quick-release couplings for the shot hose and the multifunction hose for communication with the feeding system. There is no need to connect individual cables. This saves time and eliminates connection errors.

Technical data

Installation width:

Pneumatic supply:

Control voltage:

Press-in force / path:

Cycle time:

Interfering edge / Possible component depth:

Working direction:

*Depending on the fastener and length of the shot hose.

50 / 60 / 70 / 80 mm

6 bar from feeding system

24 V / DC from feeding system

tool-dependent

up to 40 cycles/min*

according to customer requirements

vertical upwards from below

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!