Standoff / spacer as insulator

for chemical separation of materials such as steel and aluminum

blog post | September 4, 2023

Chemical separation is a key issue when it comes to avoiding undesirable reactions that impair material properties. The standoff / spacer plays an important role here as an insulator. It prevents direct contact between components and thus minimizes the risk of chemical reactions between the materials. In this article, we will take a closer look at the topic and go through the function of the spacer as an insulator for chemical separation.

Contact us

Our customer service will help you with any questions!

Contents

- Why is the separation of steel and aluminum important?

- What is a standoff / spacer and what properties make it an effective insulator?

- Structural load capacity of the spacer

- Zinc nickel coating in chemical separation of steel and aluminum

- Applications of the standoff / spacer as an insulator in various fields of industry

- What are the challenges in selecting and using the spacer as an insulator?

- Summary

Why is the separation of steel and aluminum important?

Corrosion

Steel and aluminum are different metals that need to be treated differently due to their physical and chemical properties. Chemical separation of metals can be relevant in preventing galvanic corrosion and ensuring the longevity of the materials. Direct contact of metals can lead to corrosion. For example, if these metals come into contact in a conductive solution such as water, corrosion will occur. The metal with the higher electrode potential - in this case aluminum - corrodes, while steel with the lower electrode potential is protected.

Thermal properties

Furthermore, steel and aluminum have different coefficients of thermal expansion. This means that they expand and contract at different rates with changes in temperature. These movements can cause stresses in the structure, which in turn can lead to cracks or deformation in the material.

Strength and weight

There are also differences in terms of the strength of the material and weight. Steel is generally stronger and heavier than aluminum. When these metals are used in the same construction, these differences must be taken into account to ensure that the loads are properly distributed and the construction is balanced.

Processing

Finally, the way steel and aluminum are processed and treated differs. So physical separation of these materials may also be necessary for practical reasons.

What is a standoff / spacer and what properties make it an effective insulator?

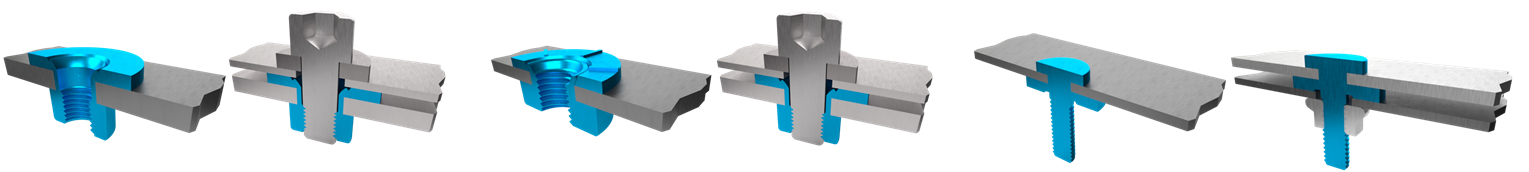

A standoff / spacer, also often referred to as a spacer screw, distance holder or distancer is a fastener used to provide a fixed distance between two components.

Its strength, heat resistance and chemical inertness make it an effective insulator. The spacer prevents unwanted reactions from occurring between the materials used by physically separating them. In addition, it is able to withstand pressures and temperatures that may occur during chemical separation.

The spacer is often made of a material that is resistant to the metals being separated, for example, a corrosion-resistant metal such as stainless steel. By protecting against corrosion, the spacer increases the life of the materials involved and the system as a whole.

Because the materials last longer, the spacer also reduces maintenance and replacement costs.

Structural load capacity of the spacer

A spacer is an important element in structures subject to high loads.

Its high structural load capacity helps to increase the stability, safety and durability of structures. The spacer is thus capable of bearing significant forces without losing its shape or function.

A spacer can help make the entire structure more stable and resistant to external influences. It helps to distribute the loads evenly and thus avoid overloading the structure. In addition, a spacer can help extend the life of the entire structure. This is because wear and premature failures can be prevented if the load is evenly distributed.

Zinc nickel coating for chemical separation of steel and aluminum

The zinc nickel coating serves as a protective layer between steel and aluminum. Without this coating, corrosion could occur when the two metals come into contact with each other. The coating on the standoff /spacer is more noble than aluminum, but less noble than steel. So it serves as a sacrificial anode that corrodes while protecting the steel and aluminum.

The zinc nickel coating provides excellent corrosion resistance, which also extends the life of the spacer. It also improves the adhesion between the spacer and the materials to be separated. In addition, the coating is very resistant to mechanical stresses and high temperatures.

Applications of the standoff / spacer as an insulator in various fields of industry

Insulation using spacers is widely used in industry, including automotive, electronics and aerospace. Materials with different properties can be effectively separated to improve product life and performance.

Automotive Industry

In the automotive industry, spacers are used as insulators in electric vehicle batteries, for example, to prevent the positive and negative electrodes from coming into contact with each other. This contact could lead to a short circuit that would damage the battery and affect the vehicle's performance.

The spacers are often made of an insulating material such as plastic and have a porous structure. This allows ions to move between the electrodes while maintaining a physical distance between them. In some cases, the spacers can also help improve heat dissipation in the battery. This is important because batteries generate heat during operation and overheating can lead to degraded battery performance or even battery failure.

Electronics and electrical engineering

In electronics and electrical engineering, spacers are often used as insulators to separate different components on a circuit board. This prevents short circuits and allows the components to work efficiently. They can also be used to dissipate heat from certain components.

Aerospace industry

In the aerospace industry, spacers can help isolate various components in aircraft and spacecraft from each other to increase vehicle safety and efficiency.

Chemical industry

Spacers are used in the chemical industry to separate different chemical substances. This is especially important when chemical reactions need to be controlled and carried out safely.

In industrial processes where substances need to be heated or cooled, spacers isolate materials from each other. This helps to regulate the temperature and prevents the substances from reacting with each other.

Food industry

Spacers are also used in food processing to separate different food components. This can help ensure food quality and safety.

Power generation

In power plants, spacers can help improve power generation efficiency and ensure equipment safety by providing insulation.

What are the challenges in selecting and using the spacer as an insulator?

Material compatibility

There are several challenges in selecting the right spacer as an insulator. First, material compatibility is key. The spacer should be made of a suitable insulator material that is resistant to the chemical properties of the materials being separated. A chemically incompatible spacer material could cause reactions that could weaken or damage adjacent materials. To avoid this, a suitable material must be determined that is compatible with the components being used.

Mechanical load

Furthermore, the mechanical load capacity of the insulator plays an important role. The spacer must be able to withstand physical stresses that occur during the separation process. It must be strong enough to bear the mechanical stress caused by the separation of the adjacent components.

Temperature stability

In addition, thermal stability should be considered, as high temperatures are often a part of the separation process. Depending on the conditions under which the materials are used, the spacer should be able to withstand high or low temperatures without losing its structure or function.

Metals expand differently when heated. This can cause stresses in the material and in the joint. The material of the spacer should have a thermal expansion rate compatible with the metals to be separated.

Electrical properties

In some applications, it may be important for the spacer to have certain electrical properties, such as conductivity or insulation capability. The life of the spacer should also be considered. It should be able to maintain its function throughout the life cycle of the components to which it is connected.

Assembly

In addition to these factors, attention should also be paid to proper assembly or positioning of the insulator. This is because an improperly placed spacer will compromise chemical separation. Precise measurement and careful placement can avoid such difficulties.

Cost

The cost of the spacer can also be an important factor, especially in industrial applications where large quantities of the fastener are processed.

Size and shape

Finally, the size and shape of the spacer must be selected to match the separation process and the materials involved. The parameters should be determined to allow effective separation between the adjacent materials.

In general, it is important to make careful design considerations for the standoff / spacer. It may also be helpful to conduct application tests to evaluate the performance of the spacer under specific conditions of the project.

Summary

In summary, standoffs / spacers play an important role in the chemical separation of materials as connecting fasteners. They serve as physical barriers that prevent the metals from coming into contact with each other and triggering undesirable chemical reactions.

Spacers are essential for steel and aluminum components, as they prevent the formation of galvanic elements that can promote corrosion. They thus ensure that the integrity and longevity of the materials are maintained. Therefore, the use of spacers is an essential step in many industrial processes and manufacturing methods.