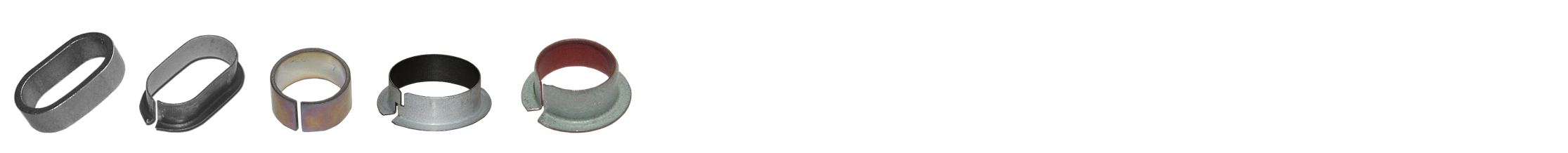

Compression Limiter

Optimal fastening of plastic components

Blog post | November 6, 2023

Plastic components are preferred for their lightness and flexibility, but they can be affected by excessive compressive loads. Unfortunately, they tend to deform or crack under pressure. These cracks can compromise the structural integrity of the material and reduce its service life. This problem can greatly affect the longevity and performance of plastic components. One solution to this problem is to use the reinforcing bushing as a compression limiter.

Contact us

Our customer service will help you with any questions!

Contents

- Importance of compression limiters

- What materials are used for compression limiters?

- Knurling of compression limiters

- Advantages of reinforcing bushings

- Applications of compression limiters in various industries

- What are the installation methods for compression limiters?

- Criteria for selecting the right compression limiter

- Summary

Importance of compression limiters

Compression limiters, also known as pressure limiters or reinforcing bushings, play a critical role in fastening plastic components in vehicles and other applications. Plastic does not have the strength to withstand the forces exerted when screws are tightened. The plastic can deform or crack, making the entire assembly unstable.

Compression limiters are therefore essential when fastening plastic components with screws. They are inserted into the intended hole in the plastic component before the screw fastener is inserted and tightened.

When the screw is tightened, the pressure that would normally have been applied to the plastic is instead transferred to the compression limiter.

The compression limiter is made of a stronger material than the plastic component and can therefore absorb the pressure without deformation or damage. In this way, the compression limiter also allows the use of stronger fasteners and higher tightening torques, which can improve the overall strength and reliability of the component.

What materials are used for compression limiters?

Compression limiters are usually made of robust and durable materials to increase the load capacity of the plastic component.

Steel

Steel is a commonly used material for pressure limiters due to its high strength and durability. It can withstand high pressure loads and provides an effective solution for demanding applications. Steel is also resistant to rust and corrosion, which increases the longevity of the plastic component.

Aluminum

Aluminum is lighter than steel yet has high strength. It is lightweight and corrosion resistant, making it a good choice for applications where weight is a concern. It still provides acceptable strength for most applications.

Brass

Brass has excellent thermal properties and is resistant to corrosion, making it ideal for applications with high temperatures and humid conditions. It is also easy to machine and offers good strength, making it an ideal choice for many industrial applications.

Coatings

Compression limiters can be coated with a variety of coatings to enhance their performance. One common coating is zinc, which offers excellent corrosion resistance.

Knurling of compression limiters

Compression limiters are not threaded because their primary function is to equalize the pressure exerted on a plastic component when a screw is tightened. A thread could cause the limiter to cut into the material, weakening the structure of the plastic part.

Compression limiters are usually equipped with knurls that serve to strengthen and stabilize the connection between the joined components.

The knurling helps to prevent the compression limiter from slipping out or turning under load. It can also improve the necessary pilot hole tolerance, which is advantageous for subsequent assembly.

Knurling is a pattern of grooves or ripples formed on the surface of the compression limiter. The knurling can have different shapes and patterns, such as straight, diagonal, cross or spiral knurling.

Advantages of reinforcing bushings

Reinforced structure

A reinforcing bushing can increase the structural integrity of a plastic part and make it more resistant to breakage or cracking. It can distribute stress around the pilot hole area, improving the strength of the entire structural part. Depending on the diameter, they can also be used for partial part reinforcement (usually large diameters).

Improved performance and extended component life

The reinforcing bushing can improve the performance of the plastic part by providing uniform load distribution and reducing the load on the part. Reducing the load on the plastic components extends their life. The components are less susceptible to damage caused by excessive pressure.

Cost efficiency

Because a pressure limiter can prevent damage and premature wear, it can help reduce the cost of replacing or repairing damaged parts.

Improved safety

By limiting the force applied to plastic components, compression limiters can also help reduce the risk of accidents and injuries.

Lightweight construction

Despite their high strength, reinforcing bushings are relatively lightweight, making them ideal for applications where weight is a concern, such as automotive, aerospace, etc.

Applications of compression limiters in various industries

Automotive industry

Compression limiters are often used in the automotive industry to protect plastic parts such as shock absorbers, mirror mounts or fittings. They prevent these parts from breaking or deforming under high pressure. Carbon fiber components are used in high-performance and racing cars because of their lightweight construction and high strength. Here, too, reinforcing bushings help extend the service life of these components and improve their performance.

Electronics industry

In electronic devices such as computers, cell phones or game consoles, pressure limiters can help protect plastic components that are exposed to pressure.

Household appliances

In appliances such as washing machines, dishwashers or refrigerators, compression limiters can protect plastic parts from pressure.

Aerospace

In this industry, compression limiters are used in aircraft and satellites, among other applications, to protect plastic parts from the high pressure loads that can occur during flight.

Wind energy

Carbon fiber reinforced plastics are used in the manufacture of wind turbine blades. Reinforcing bushings can help ensure the longevity of these blades by preventing cracks from forming.

Food industry

In food processing machinery, compression limiters can help protect plastic parts from the pressure generated, for example, by pumps or other processes.

What are the installation methods for compression limiters?

Clinching / riveting

In this method, the pressure limiter is force-fitted into a prefabricated pilot hole in the plastic component after the part has been manufactured. This can be done manually or with a press. To anchor the pressure limiter very securely in the component, it can also be riveted. This means that a riveted collar on the limiter is riveted around the hole to a defined diameter. This means that there is a collar on both sides and the compression limiter is optimally secured against falling out.

Molding

The compression limiter is inserted directly into the material during the injection molding process and is thus firmly integrated into the plastic component. This means that the reinforcing bushing is placed in the mold before the material is poured in. When the material hardens, it surrounds and secures the bushing, which is then firmly embedded. This requires a special mold and can create a very strong and permanent bond. This method offers the advantage that no subsequent machining is required.

Ultrasound

In this process, the reinforcing bushing is welded into the plastic component by ultrasound. The ultrasonic method uses vibration to melt the surrounding plastic and easily insert the compression limiter.

Heat insertion

In this method, the compression limiter is heated and then inserted into the plastic component. The heat melts the plastic around the pressure limiter and forms a strong bond as it cools and hardens.

Bonding

In this process, a special adhesive is used to secure the reinforcing bushing in the hole of the plastic part. This adhesive cures and forms a strong bond between the bushing and the plastic part.

Criteria for selecting the right compression limiter

When selecting a compression limiter, you should consider several factors. The compression limiter should be made of a material that is resistant to the stresses and environmental conditions encountered in the application. It should be specifically suited for the plastic that will be used in the specific application. Not all compression limiters are suitable for all plastics.

Size and shape are equally important, as they affect the fit and effectiveness of the pressure limiter. The size and shape of the reinforcing bushing should be matched to the plastic component. A pressure limiter that is too large or too small could damage the component or impair its function. The knurling of the compression limiter should also be taken into account, as this provides additional holding force.

You should also consider the type of load that will be applied to the component. The compression limiter should be able to withstand the expected loads without deformation or breakage. If the component will be subjected to a high pressure load, a compression limiter with a flanged head would be a good choice. Make sure that the compression limiter has sufficient load capacity to withstand the maximum compressive load of the plastic component. The reinforcing bushing should be able to handle the expected pressure without deformation or cracking.

When installing, you should select the appropriate installation method based on the plastic material and the design of the component. The compression limiter should be easy to install and provide a secure connection to the plastic component.

Summary

Compression limiters play a crucial role in securing and stabilizing plastic components. They are used in many industrial applications to extend component life and ensure safety. Their ability to absorb compressive forces from screws prevents components from cracking or loosening under load. They are specially designed to strengthen and protect the plastic around them.

The use of pressure limiters is therefore essential to ensure the longevity and functionality of plastic components. With their help, the safety and stability of plastic components is significantly improved. Thus, compression limiters offer a cost-effective and durable solution for ensuring the structural integrity of plastic components.