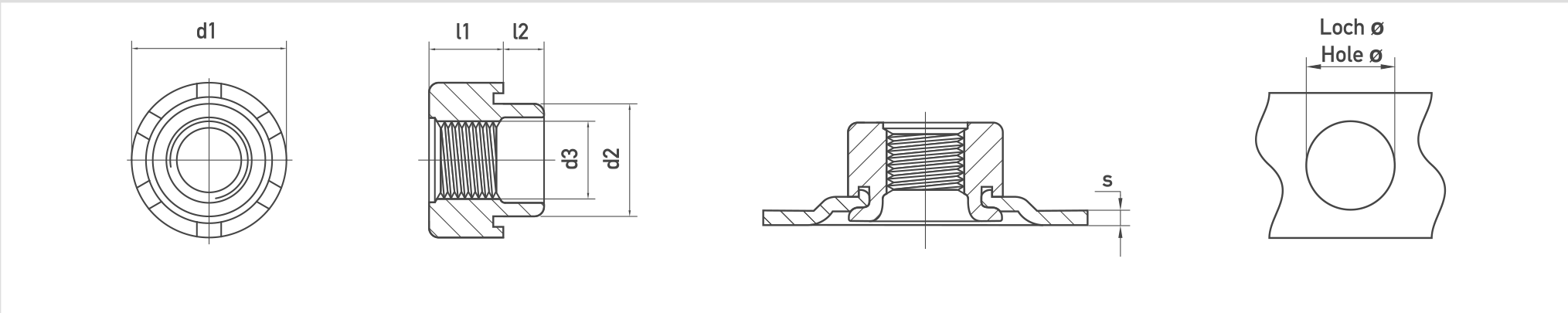

ARN rivet nut

for automated feeding and processing

Rivet nut for highest torque and push-out forces, for ordinary pull-through forces. Suitable for water-tight and gas-tight applications. In use at car manufacturers (OEM) in Germany, Europe and the USA.

Sheet thickness - Used for metal sheets with thicknesses from 0.7mm to 3mm

Thread - M5, M6, M8, M10, M12, M14

Workpiece material - Steel, aluminum, copper, magnesium

Outer diameter - Medium

Pull-through force - High

Torque - Very high

Push-out force - Very high

| Thread (d3) | Outer diameter in mm (d1) | Collar diameter in mm (d2) | Height in mm (l1) | Max. collar height in mm (l2) | Polot hole diameter in mm (Ø -0,1) | Sheet thickness in mm (s) |

|---|---|---|---|---|---|---|

| M5 | 13.00 | 9.00 | 5.50 | 3.50 | 9.15 | 0.70 - 3.00 |

| M6 | 13.00 | 9.00 | 5.50 | 3.50 | 9.15 | 0.70 - 3.00 |

| M8 | 16.00 | 11.50 | 7.50 | 4.00 | 11.65 | 0.70 - 3.00 |

| M10 | 19.30 | 14.80 | 9.60 | 4.50 | 14.95 | 0.70 - 3.00 |

| M12 | 23.00 | 15.70 | 11.50 | 4.50 | 15.85 | 0.70 - 3.00 |

| Thread | Material | Sheet thickness (mm) | Push out force (kN) | Torsional strength (Nm) |

|---|---|---|---|---|

| M6 | Steel | 0.7 | 3.9 | 17 |

| M6 | Steel | 1.0 | 4.1 | 20 |

| M6 | Steel | 1.25 | 4.1 | 20 |

| M6 | Steel | 1.5 | 4.5 | 21 |

| M6 | Steel | 1.75 | 4.7 | 19 |

| M6 | Steel | 2.0 | 4.9 | 19 |

| M6 | Aluminum | 0.8 | 1.3 | 11 |

| M6 | Aluminum | 1.0 | 1.7 | 12 |

| M6 | Aluminum | 1.2 | 2.2 | 20 |

| M6 | Aluminum | 1.5 | 2.9 | 21 |

| M6 | Aluminum | 2.0 | 4.0 | 22 |

| M8 | Steel | 0.7 | 4.0 | 25 |

| M8 | Steel | 1.0 | 4.2 | 33 |

| M8 | Steel | 1.25 | 4.7 | 45 |

| M8 | Steel | 1.5 | 5.0 | 51 |

| M8 | Steel | 1.75 | 5.7 | 52 |

| M8 | Steel | 2.0 | 6.0 | 60 |

| M8 | Aluminum | 0.8 | 1.2 | 23 |

| M8 | Aluminum | 1.0 | 1.8 | 26 |

| M8 | Aluminum | 1.2 | 2.3 | 31 |

| M8 | Aluminum | 1.5 | 3.5 | 36 |

| M8 | Aluminum | 2.0 | 3.5 | 45 |

These values are for orientation only and are not binding.

Tests were conducted in steel H320 LA and aluminum EN AW-5754.

| Thread proof load | Pitch x thread | Thread tolerance | Thread coating as an option | Surface finish | PVT as an option |

|---|---|---|---|---|---|

| according to class 8, 10 | 0.8 x d | 6G, 6H | Nycote, Precote | Various surface coatings possible | Yes |

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!

Application and function

Suitable for: Insertion in metal sheets with tensile strength less than 800N/mm², water-tight and gas-tight applications

Sheet metal bottom: Indentation on sheet metal bottom. The rivet collar is approx. 0.2mm behind sheet metal bottom

Pilot hole preparation: Pre-punched pilot hole with embossing according to AUTORIV specifications

Die: Use of a special rivet die. Rivet collar or die should be oiled

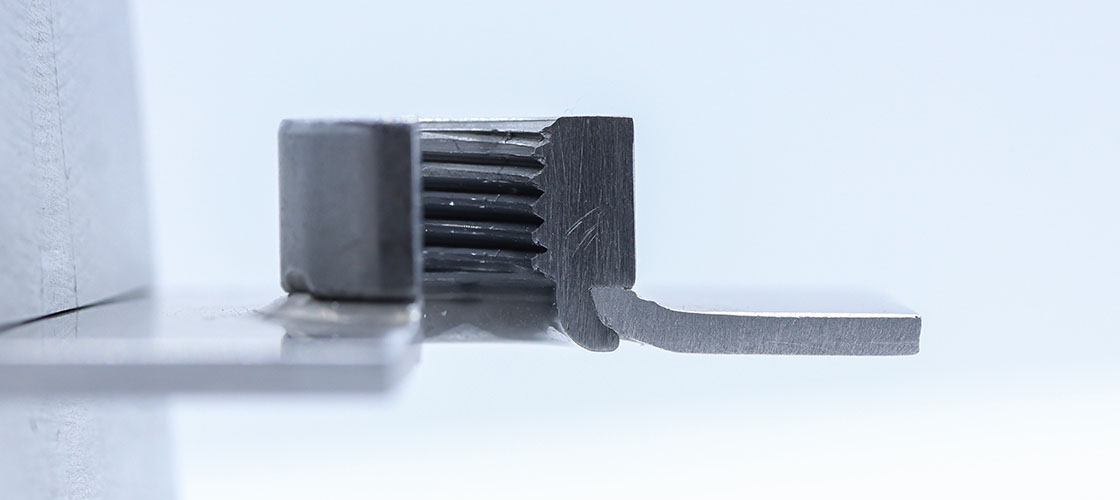

Installation: The rivet collar is formed and folded over the sheet metal. The wedge under-head ribs are pressed into the sheet metal during the setting process.

Outer diameter - pull-through force: Medium outer diameter, also suitable for aluminum applications, good pull through force

Under-head serration - torque: Wedge under-head ribs for high torque absorption, especially in higher-strength metal sheets

Collar - push-out force: Formable rivet collar that folds over the sheet metal and provides a very high push out force

Highlights

Highest possible torque and push-out forces, better than with clinch nuts or self-piercing nuts

Customized solutions for sheet thicknesses above 3mm possible

- No diversity, less stock requirement

- No risk of mix-up (Incorrect fasteners in incorrect application)

- (Re-)use of existing automation / tooling, thus reduction of investment

- Suitable for sheet metal tensile strengths where conventional clinching fasteners or self-piercing nuts can not be used, from 600Mpa to approx. 800Mpa limit

- For custom applications, sheet metal with tensile strength from 800Mpa to 1,400 Mpa or higher is suitable