STN clinch stud

for automated feeding and processing

Clinch stud / screw for highest torque and push-out forces. This clinch stud with outstanding performance holds better than any other clinch stud on the market, especially in thin and soft metal sheets. In use at car manufacturer OEMs in the USA. New development, other OEMs to follow.

Sheet thickness - Used for metal sheets with thicknesses from 0.7mm to 2.5mm

Thread size - M6, M8, M10

Workpiece material - Steel, aluminum, copper

Outer diameter - Large

Pull-through force - High

Torque - Very high

Push-out force - Very high

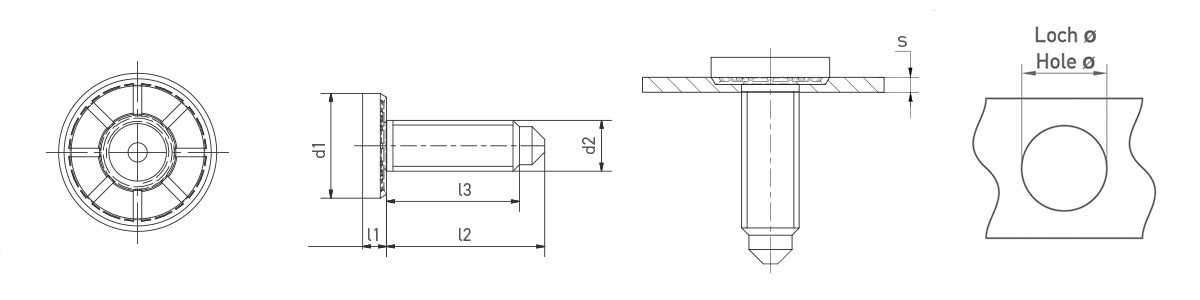

| Thread (d2) | Head diameter in mm (d1) | Head height in mm (l1) | Collar height | Sheet thickness in mm (s) | Pilot hole diameter in mm (Ø -0,1) | Thread length in mm (l3) |

|---|---|---|---|---|---|---|

| M6 | 14 | 3.80 | 0.70 | 0.70 - 2.50 | 6.20 | 16 / 20 / 25 / 30 / 35 / 40 /45 |

| M8 | 16.50 | 3.80 | 0.70 | 0.70 - 2.50 | 8.20 | 20 / 25 / 30 / 35 / 40 / 45 / 50 |

Tolerances according to ISO 2768-m.

| Thread | Material | Sheet thickness (mm) | Push-out force (kN) | Torsional strength (Nm) |

|---|---|---|---|---|

| M6 | Steel | 1.15 | 0.70 | 10 |

| M8 | Steel | |||

| M10 | Steel |

These values are for orientation only and are not binding.

Tests were conducted in steel 20MnB4.

| Thread proof load | Thread length | Thread ends | Thread tolerance | Thread coating as an option | Surface protection |

|---|---|---|---|---|---|

| according to class 8.8, 9.8, 10.9 possible | according to customer requirements | according to standard, as well as MaThread | 6g, 6h | Nycote, Precote | Various surface coatings possible |

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!

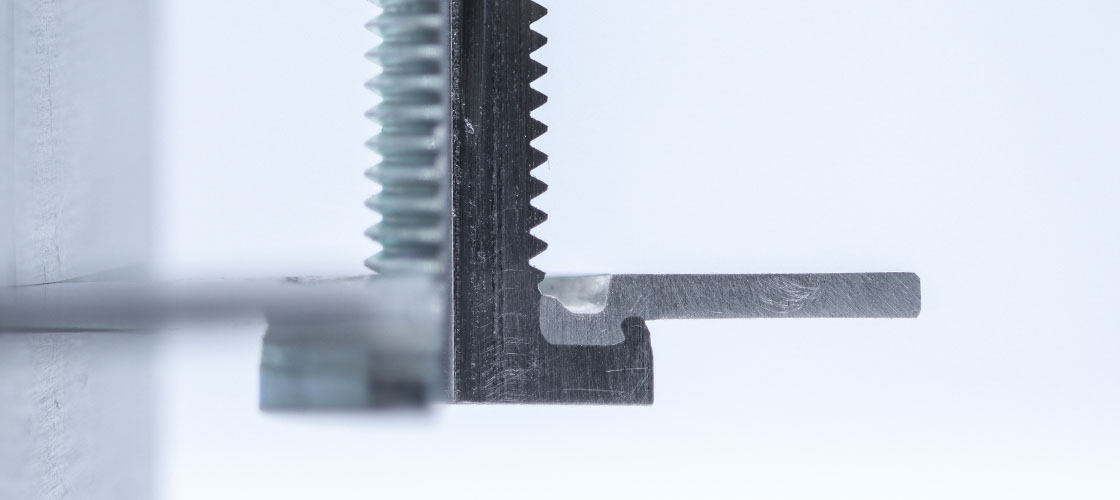

Application and function

Suitable for: Insertion in metal sheets with tensile strength less than 800N/mm²

Sheet metal bottom: Indentation on sheet metal bottom

Pilot hole preparation: Pre-punched pilot hole according to AUTORIV specifications

Die: Use of a special embossing die

Installation: The sheet metal is pressed into the annular groove of the nut and moves into the outer undercut and in the case of thicker sheets into the inner undercut

Outer diameter - pull through force: Large head diameter, also suitable for aluminum applications, good pull through force

Under-head serration - torque: Lengthwise under-head ribs in the embossing area for high torque absorption

Collar - push out force: Collars with undercut around the thread and around the outer diameter to provide very high push out forces

Highlights

Higher torque and push out forces than with conventional clinch studs

- No diversity, less stock requirement

- No risk of mix-up (Incorrect fasteners in incorrect application)

- (Re-)use of existing automation / tooling, thus reduction of investment

Greater compensation possible with custom design, possible with suitable AUTORIV thread end

- Ensuring optimal pressing: No "NOK pressings" with risk of subsequent complaints and quality costs

- No frequent re-teaching of the robot necessary

- Ensuring high availability and output, thus cost reduction

- Easier positioning compared to studs that are placed in narrow pilot holes

- Lower chip formation due to abrasion of the thread on the edge of the pilot hole