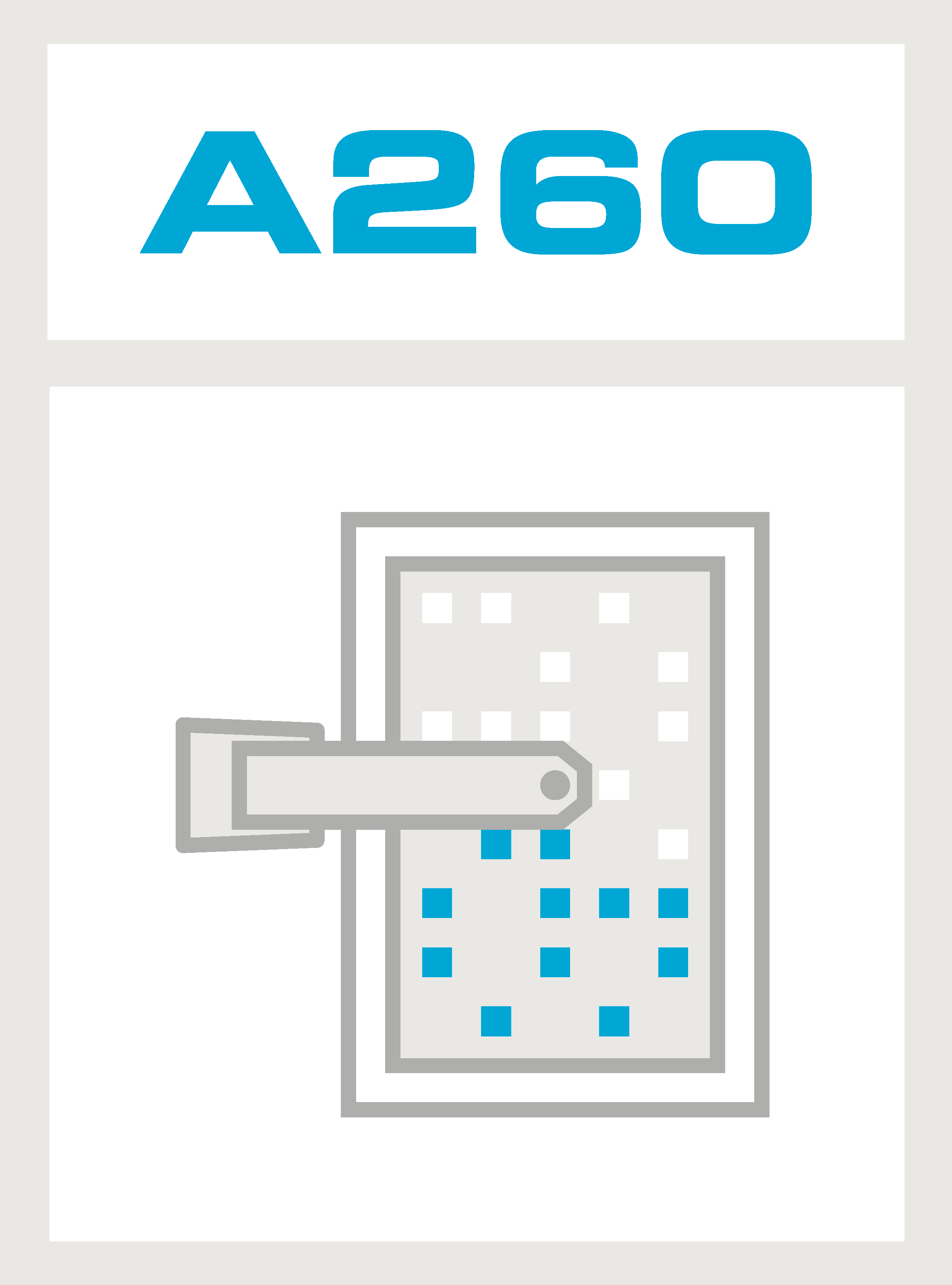

CNC system

for processing fasteners

The A260 assembly system is a stationary CNC system for processing various fasteners. The positions of the fasteners to be set are approached via x, y, z axes. The fasteners are installed into the component with the appropriate setting unit.

The processed sheet metal component can be inserted by the operator or robot. Depending on the design, the setting units can be guided to the component as well as the component itself can be moved. The fasteners are fed via a feeding system.

Different designs - The modular design of the CNC system allows different combinations of setting units adapted to your specific requirements, the processed component and the fasteners.

Advantages of the system

- Fully automatic, reliable processing of fasteners

- Short cycle times

- Efficient tool movements with minimum wear

- Cost savings due to automatic loading, feeding and setting processes

- Feeding system and controller module outside the danger zone

- Process monitoring with force-displacement evaluation

Request for quotation

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!